- Our solution

- Chamber base

- Complete chambers

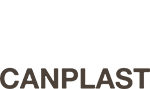

- Canplast Pro© freestanding chambers

- Drop chamber

- Flow-break chamber

- Chambers for protection zones

- Unitary and separative system

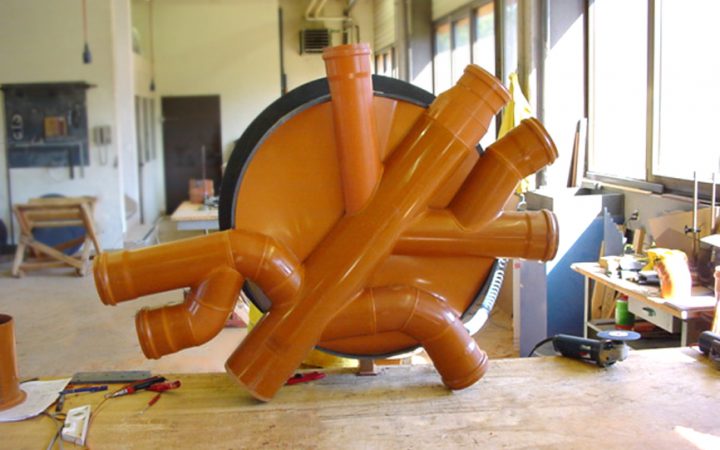

- Cable chambers

If you are looking for a simple, fast and long-lasting solution, all you need to do is explain your project to us and we will supply to you the inspection chamber that is most adapted to your needs.

For over 50 years, Canplast inspection chambers have proven their worth due to their comparative advantages and adaptability, which allow them to meet the requirements of all our clients' projects.

A perfect solution

As a general rule, that chambers must be made of the same material as the pipe. But what if a pipe is made of PVC, PE or PP ? Is it possible to make a chamber in these materials ? How can we build it ? How can we install it ? Will it not be too fragile, too flexible or too unstable ?

To these questions, Canplast replies as follows :

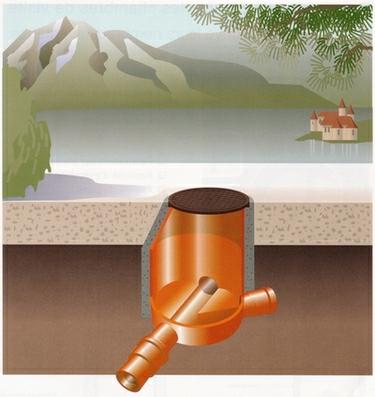

The custom made plastic chamber is used as a "watertight freestanding formwork to be concreted." It is delivered on site while the work is in-progress. It is then connected to the pipe which has already been laid, levelled, shuttered and encased with concrete. The result is a concrete chamber, lined with plastic inside. The perfect chamber !

The use of synthetic chambers makes it possible to elegantly solve the problems that are usually affecting the construction of traditional concrete chambers. They undeniably improve the quality of the work while maintaining short lead times and a cost advantage.

While the general use of custom made plastic chambers is recent, the concept itself is not new! Our company laid the first ones in 1966 in the canton of Vaud. Since then, the use of plastic "freestanding formwork" for civil engineering has become widespread and it is now a "must" for any engineer who appreciates a well-done job. Nowadays, when inspected, these chambers are always impeccable and now constitute the long-term point of reference rightly demanded by engineers, architects and project managers. Canplast custom made prefabricated chambers in PVC, PE or PP always offer complete adaptability with respect to the designer’s requirements.

The advantages of our chambers

- Watertightness : Culverts, pavements, shafts, and all connections to the collector are completely watertight.

- Abrasion resistance : PVC, PE and PP have an excellent resistance to abrasion caused by sand and gravel carried by runoff.

- Corrosion resistance : The materials have an optimum resistance to corrosion caused by household and industrial wastewater.

- Hydraulic operation : The favourable roughness coefficient and the perfect geometry of the moulded base reduce capacity losses and eliminate deposits as well as encrustations on the base and walls of the culvert.

- Uniformity of the pipe network : When a collector is built with pipes made of synthetic material, it makes sense to build inspection chambers in the same material since the technical requirements that dictated the choice of the pipes also apply to the chambers.

- Ease of installation : The execution of an English-type PVC, PE or PP culvert does not require the use of a qualified workforce by the company. Overseeing of this work by the supervisor becomes unnecessary.

- Speed of installation : The installation of the Canplast chambers is performed at the same pace as that of the pipes, thus the execution times are reduced.

- Instant commissioning : Delivered as the work progresses, the chambers are laid at the same time as the pipes.

- Custom-made : They can be freestanding or encased in concrete.

Discover our choice of dimensions

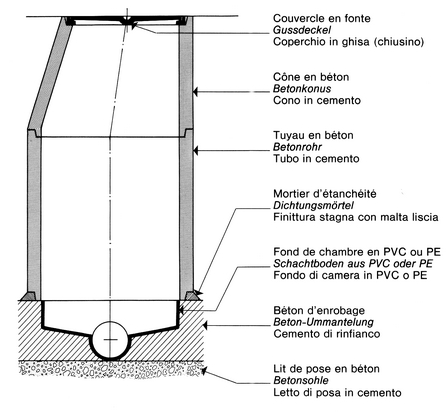

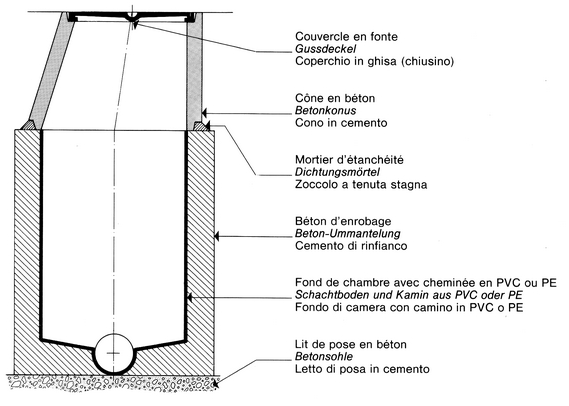

TYPE 1

The diameter of the plastic base is equal to that of the shaft made of concrete rings. The majority of chamber bases are made of PVC, but PE is recommended in special cases (high impact resistance, very aggressive water, laying of welded pipes, etc.). PP is recommended for high temperatures. The diameters most commonly used for plastic chamber bases are: Ø 800 mm, Ø 900 mm, Ø 1'000 mm and Ø 1'200 mm.

Standard height of the Canplast chamber base = collector Ø + 150 mm.

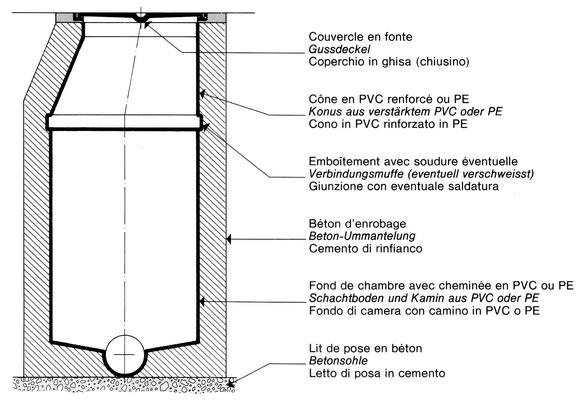

TYPE 2

The diameter of the plastic base is smaller than that of the shaft made of concrete rings. For oval concrete shafts, or for shafts with a diameter greater than the plastic base. This solution comes with the following advantages:

- Lower price compared to type 1.

- Possibility to offset the shaft in relation to the plastic base.

- Possibility of sealing mortar after backfilling.

- Possibility of installing a sealing joint around the plastic base.

The diameters most commonly used for plastic chamber bases are: Ø 630 mm, Ø 710 mm, Ø 800mm, Ø 900 mm and Ø 1'000 mm.

Standard height of the Canplast chamber base = collector Ø + 150 mm.

Canplast chamber

With synthetic shaft

| Custom-made in PVC, PP or HDPE (PP: see Canplast Pro© freestanding chambers) |

| The chambers, with plastic shaft, are generally used for the collectors situated in the water table. Depending on the height, the shaft must be concreted in several stages. The chamber must be wedged in order to prevent movement during concreting.

The diameters most commonly used for plastic chamber bases are 800 mm and 1'000 mm. |

Canplast Complete Chamber

|

|

|

The complete Canplast chamber offers optimum resistance to the fumes produced by wastewater over its entire surface. This solution is generally adopted on the worksites during the installation in the apron, especially in the presence of a water table. The diameters most commonly used for plastic chamber bases are 800 mm and 1'000 mm. |

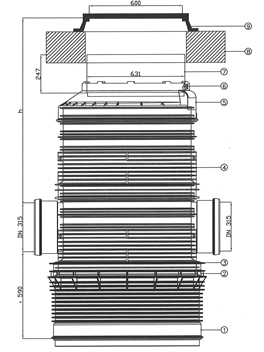

In addition to its inspection chambers used as watertight freestanding formwork, Canplast offers its Canplast Pro© chambers in PP, freestanding, guaranteeing durability, safety, ease of installation and operation.

With their modular design, many configurations can be realised in our manufacture workshops, custom-made and according to the needs of the project as well as the demands of the company and engineer in charge.

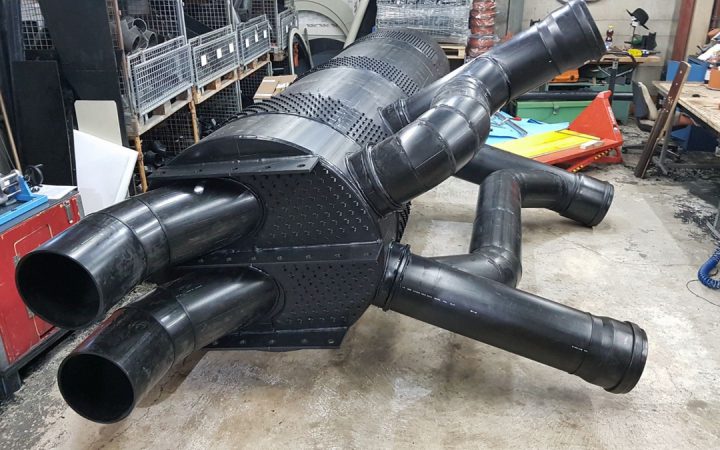

Our range of products

Complete range

- Diameter of the chambers: 600, 800 and 1'000 mm

- Diameter of the pipes: 160, 200, 250, 315, 400 and 500 mm

Adjustable, with different heights available

PRO 600, PRO 800 and PRO 1'000: Telescopic extension possible

Applications

Chambers for connecting, inspecting, cleaning and visiting non-pressure wastewater and rainwater drainage networks.

Characteristics, reference standards and quality trademark

- Chamber base and shafts in PP (Polypropylene)

- Colour: Brown Orange

- Modular type

- Water table: reinforced base and peripheral ribs

- Telescopic extension possible

- Inputs, outlets and custom made gradients

- Access by cast iron cover on distribution slab

- Standard EN 13598-1 for PRO 600©

- Standard EN 13598-2 for PRO 800© and PRO 1'000©

Qualities and advantages

- Lightness, ease and speed of installation ("ready to install” delivery possible, assembly of components in our manufacture workshops)

- Guaranteed watertight

- Exceptionally high rigidity of the extension: double wall CR8 minimum PP

- Mechanical resistance to impact, abrasion and corrosion

- Ease of operation, available access scale (rungs)

- Dimensional compatibility with all plastic pipes (PVC-PE-PP)

- Adaptability according to plan of the technical office

- Longevity of networks - fully recyclable PP

Example below: Standard Canplast Pro© chamber Ø 800 mm with dump

|

|

Chamber Ø

(mm) |

Collector Ø

(mm) |

Secondary inlets

(mm) |

Height

(mm) |

Price

(CHF) |

|

630

|

160, straight

|

-

|

400

|

265.--

|

|

630

|

160, straight

|

2x 160

|

400

|

295.--

|

|

630

|

200, straight

|

-

|

400

|

270.--

|

|

630

|

200, straight

|

2x 200

|

400

|

330.--

|

|

630

|

250, straight

|

-

|

500

|

378.--

|

|

630

|

250, straight

|

2x 250

|

500

|

514.--

|

Adaptability in our manufacture workshops

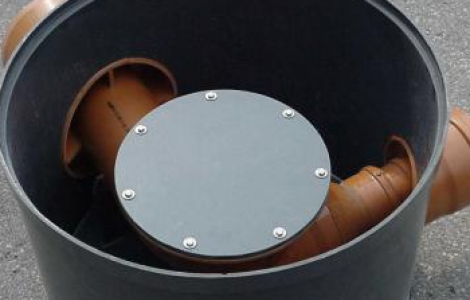

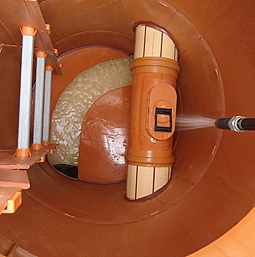

Figure 1: Element with rungs incorporating a pipe with cleaning hatch

Figure 2: Interior of a chamber with rungs

Control and delivery

Figure 3: Shut-off for chamber inspection.

Figure 4: Chamber watertightness control

Figure 5: Laying a room to fill.

The drop chamber is ideal in order to modify the level between the inlet and outlet of a manhole. This solution helps controlling and the cleaning the collectors, and it is well adapted when the gradients are slight.

Unitary system

Separative system

Advantages

This method significantly reduces the volume of excavation and backfilling. Only one cast iron cover and one shaft are needed instead of two, when using traditional chambers. Through various control opening systems, contact between clean water and wastewater networks is avoided.

Special cases

Custom made manufacturing provides a guarantee of cleanliness and precision.

The use of synthetic chambers for electric cables definitely solves the problems that arise during the construction of traditional concrete chambers, by greatly improving the quality of the finished structure.

After strict controls, they always appear clean and impeccable. They rightly constitute the long-term golden standards required by electricity services.