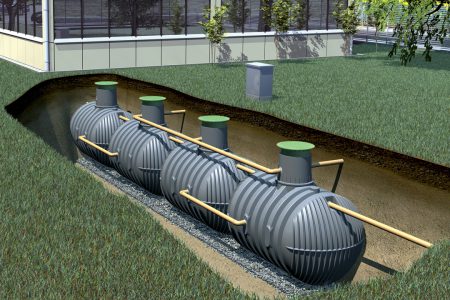

Although the majority of dwellings in Switzerland are connected to a centralised treatment plant through a collective sanitation system, there are several cases where the use of an individual treatment solution remains the best solution, especially in rural areas.

The « digestion tank + self-priming chamber + infiltration trench » has been used by Canplast for nearly 20 years in areas where hydrogeological conditions and environmental requirements allow it.

Klaro non-collective sanitation system, Canplast offers high quality solutions that are easy to set up (light weight).

Klaro mini-treatment plant

The Klaro mini-treatment plant works with the sequencing batch reactor (SBR) (Sequencing batch reactor). No pump, no current conductor and no mechanical part moving in the tank. Hoses provide air transfer between the compressor and the purification system. The compressor sends air through a membrane tray in order to aerate the treatment chamber and purify the wastewater.

The compressor and the technical components are pre-installed in a control cabinet, which is to be installed either in a room inside the house, or in a box outside. The compressor stands out for its longevity and low sound level.

Easy maintenance

The whole installation is controlled by the compressed air management technical cabinet (low sound level), which is installed either in a technical room inside the house, or in a box outside, so it is easy to access. On the screen, one can read the total hours of operation of the system. Power outages are identified with an audible and visual alarm. All components of the control cabinet can be easily replaced. The conception of the cabinet allows easy maintenance and is inexpensive.

Simple assembly

A colour code facilitates the connection of the air hoses between the control cabinet and the SBR treatment system in the tank. No connection error is possible. The SBR system is pre-equipped with fittings for fixing the air hoses. In the case of a single tank (Klaro Quick), the SBR system is simply positioned on the partition wall and mounted in series on the tank. The SBR system is conceived to be assembled quickly without tools. For mini-treatment plants consisting of two tanks (Klaro Easy), the SBR system is always pre-assembled in our workshops.

Flexible and modular

The treatment system can be adapted to the conditions of use. The original setting can be modulated by changing the cycle times, in order to adapt it to the actual conditions of use. During periods of prolonged absence (e g..: holidays) a simple intervention on the control cabinet makes it possible to put the installation in "holiday" position. The mini-treatment plant can absorb a temporary overload (a weekend) of 25% without specific adjustment. The "comfort package" is an option offering a keypad as well as an under load detector. Treatment solutions up to 200 EH are available upon request.

Operating principle of the Klaro mini-treatment plant

According to the directives of the canton concerned and the volumes to be processed, Canplast offers the possibility to operators to subscribe to a maintenance contract. Canplast provides a unique maintenance service in French-speaking Switzerland, including, in particular:

- A guarantee on parts and labour

- Operation control

- Technical control

- Maintenance of installation components that require it

- Planning of sludge emptying

- Effluent tests according to the requirements of the competent cantonal authority

- Drafting of a service report and delivery of the document to the owner, the municipality and the cantonal authority

- Federal Act on Water Protection (LEaux, 1991)

- Federal Ordinance on Water (OEaux, 1998)

- Guideline for selection, type and sizing of low capacity wastewater treatment plants (VSA, 1995)

- Memorandum for the planning, assessment, operation and maintenance of wastewater disposal and treatment systems for Isolated lands and small agglomerations (VSA, 2006)

- European standard EN 12566-3 on small wastewater treatment plants up to 50 PTE

- Cantonal directives on individual treatment

| Mini-station |

Klaro

|

| Purification system |

SBR

|

| Application |

High performance and maximum user comfort with

many accessories available |

| Standard up to |

18 EH

|

| On request until |

200 EH

|

| Emptying |

1-2 times per year

|

| Plastic materials guarantee |

25 years

|

| Purification system guarantee |

3 years

|

| Sampling kit |

integrated

|

| Denitrification |

optional

|

| Phosphating |

optional

|

| U.V. treatment |

optional

|

| “Comfort” pack |

optional

|

| Power outage detection |

integrated

|

| Temperature sensor |

optional

|

| “Holiday” mode |

optional

|

| Remote monitoring (modem) |

optional

|

| External control cabinet |

optional

|

| Limit rates |

VSA Directive limit values (2006)

|

Klaro purification performances***

|

| COD (Chemical Oxygen Demand) |

90 mg/L

|

44 mg/L

|

| BOD5 (biochemical oxygen demand after 5 days) |

30 mg/L

|

5 mg/L

|

| SS (suspended solids) |

30 mg/L

|

6 mg/L

|

| NH4-N (ammoniacal nitrogen) |

3 mg/L

|

0,3 mg/L

|

*** Results of the tests carried out on the approved platform of Aix-la-Chapelle (France).