Plastic pipes, free-flowing

Canplast laid the first PVC pipes in 1965, PE-HD in 1980 and PP-HM in 2005.

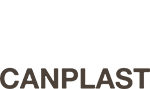

We offer many solutions in order to provide you with advice, as well as with the various plastic pipes available on the market: pipes made of polyvinyl chloride (PVC), of polypropylene (PP) and of polyethylene (PE).

The three types of pipes must comply with the European standards in application (EN1401 for compact PVC, EN 12666 for PE-HD, EN 1852 for PP-HM and EN 13476 for structured pipes).

- Corrosion resistance

- Watertightness of walls and joints

- Abrasion resistance

- Lightness

- Easy installation

- Low roughness

- High modulus of elasticity

- Great flexibility

- Low prices

- Recyclable material