Context

The advancement of knowledge and production technologies now make it possible to manufacture PVC pipes without the addition of heavy metals. During manufacture, the hydrochloric acid produced by the process of dechlorination of the PVC molecule, damages the chemical structure of the molecule so causing a significant depletion of the mechanical characteristics. To avoid this phenomenon, the stabilisation of this acid is essential. In the past, stabilisation was achieved by adding lead or heavy metals. Nowadays, these old stabilisers have been replaced by organic stabilisers, which improves the properties of the PVC material and eliminates the ecological issues of heavy metals.

Application

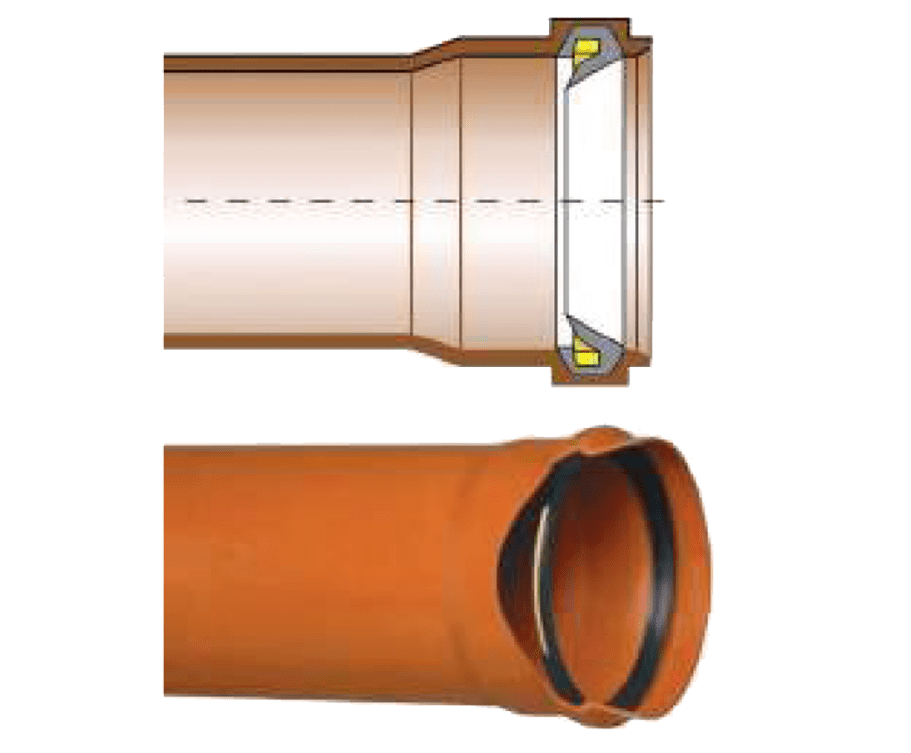

Sewage, rainwater and drainage networks. Underground ventilation ducts and Canadian wells.

Standardisation

The SIA 190 standard (2000 edition, page 23) requires, for PVC pipes without overpressure (gravity flow), the application of SN EN 1401-1 standard. This standard is the most stringent for the manufacture of PVC pipe with SN 2, SN 4 and SN 8 rigidities. Structured PVC pipes are not allowed by the EN 1401-1 standard.

Physical and mechanical characteristics

The SIA 190 standard (2000 edition, page 23) requires, for PVC pipes without overpressure (gravity flow), the application of SN EN 1401-1 standard. This standard is the most stringent for the manufacture of PVC pipe with SN 2, SN 4 and SN 8 rigidities. Structured PVC pipes are not allowed by the EN 1401-1 standard.

| Specific weight | 1'380 kg/m3 |

| Modulus of elasticity (value for a minute) | 3'000 N/mm2 |

| Modulus of elasticity (long-term value) | 1'500 N/mm2 |

| Tensile strength | 20 N/mm2 |

| Average coefficient of longitudinal elongation | 0.08 mm/m K |

| Ring stiffness available | SN2 (2 kN/m2) SN4 (4 kN/m2) SN8 (8 kN/m2) SN12 (12 kN/m2) SN16 (16 kN/m2) |

Materials and ecology

Ecological PVC is distinguished from "traditional" PVC by its composition which no longer contains heavy metals.

PVC pipes stabilised with calcium and zinc stearate (PVC Ca-Zn) or organic stabilisers (OBS) are recommended by the Swiss Research Centre for Rationalization in Building and Civil Engineering (CRB). In the chapter of CAN 237, PVC Ca-Zn is classified in the best category with the mention "ecologically interesting." It is ranked equally with polyethylene (PE) and polypropylene (PP). Fiberglass-reinforced polyester pipes are not recommended.