Application

To avoid the passage of undesirable particles, which may clog the outlet pipe, the use of an adaptable and removable strainer for cleaning the pipe is a technical advantage.

Description

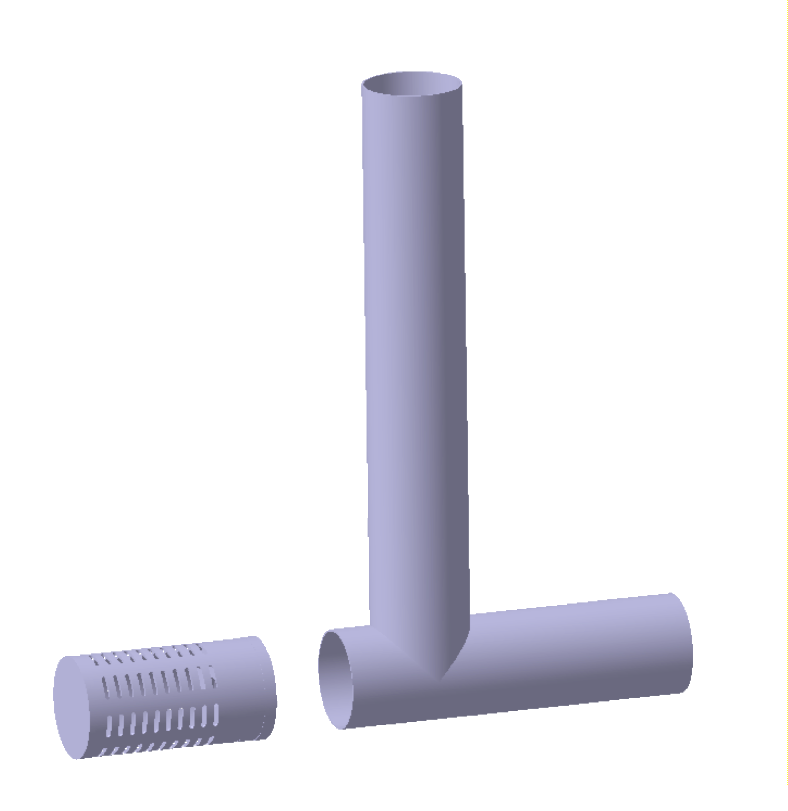

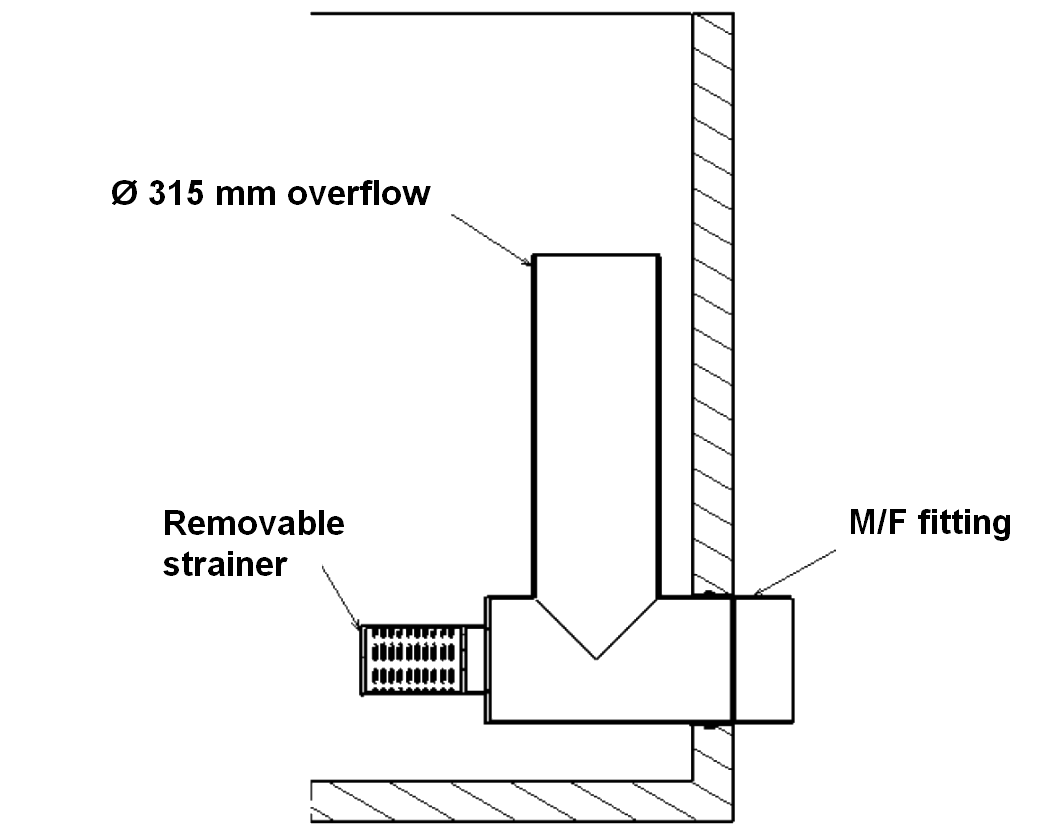

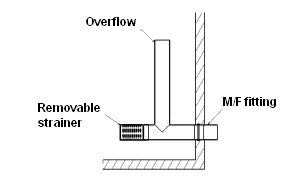

In general, the flow limiter can be made according to the figure above and can be composed of the following elements:

- A removable strainer made to measure usually with an outside diameter of 160[1] mm

- A calibrated orifice

- An overflow[2] (recommended).

All elements of this flow limiter, in PVC, are custom-made, in order to guarantee an optimal flow.

[1] Different diameters are available: Ø 110, 125 160, 200, 250, 315, 400 mm, etc.

[2] Depending on the length of the overflow, a clamp may be required.

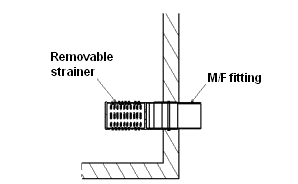

Strainer

The threaded strainer ensures easy installation and disassembly for maintenance/cleaning of the outlet pipe. Various options are available to the clients, depending on the particular needs.

Advantages

The advantages of the strainer are as follows:

- No moving mechanical parts

- High reliability

- The section and the number of grooves guarantee optimal flow

- Calibrated orifice integrated into the strainer

- Easy and quick installation and disassembly

Assembly and conditions to be respected

The general conditions to respect in order to install a strainer are as follows :

- Depending on the case, a method of fixing must be provided. Canplast is willing to provide this fixing system.

- Assembly and disassembly of the strainer using the threaded fixing system.

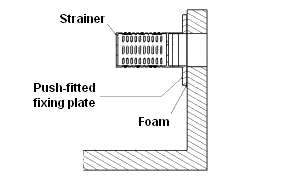

| Case 1: Removable strainer to fit | Case 2: Removable strainer with overflow to fit |

|

|

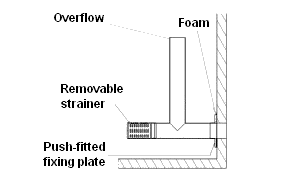

| Case 3: Removable strainer with flat surface fixing plate or curvilinear surface | Case 4: Removable strainer with overflow and flat surface fixing plate or curvilinear surface |

|

|

Figure 1: Display of the various possibilities of realisation

Figure 2: Flow regulator display with Ø 160 mm strainer and Ø 315 mm overflow