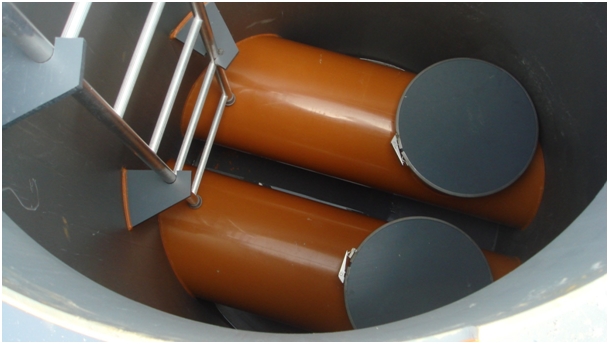

Prefabrication

The contractor can save in several ways.

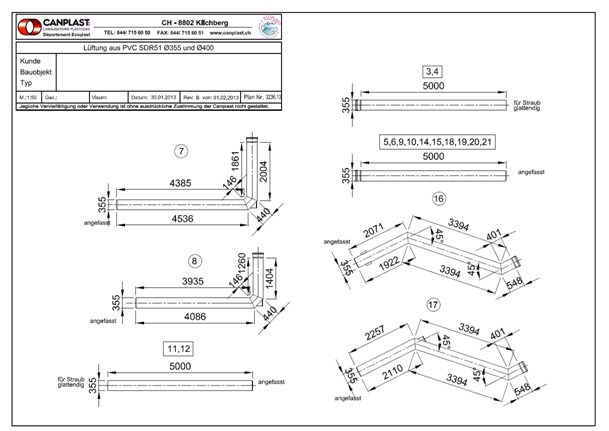

- Custom made manufacturing allows the ordering of only the quantities of pipes required, there are no more cuts or waste.

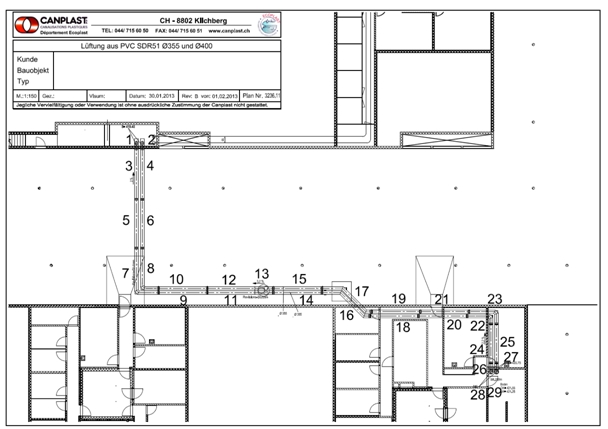

- There is no longer the constraint of forms imposed by the dimensions of standard parts.

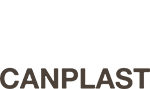

- The prefabrication of large elements causes a decrease in the number of assemblies.

- The numbering of the elements facilitates the work for assemblers.

- The manufacturing of custom made elements can be adapted to the requirements of the technician for all parts requiring particular radii of curvature or variations of sections.

The Canplast technical service is at your disposal to help you choose the most suitable material for your project.

PVC and PE are available between Ø 110 mm and Ø 1'200 mm. For larger diameters, it is possible to make PE-Bauku© sheaths.

The details of backfilling or concrete encasement will be studied on a case by case basis depending on the loads and the risks of differential settlements.

Materials

- PVC Compact organic-based (OBS), heavy-metal-free PVC recommended by Eco-Devis 237 and compliant with EN1401-1 and SIA 190 standards.

- HDPE sleeved or smoothed