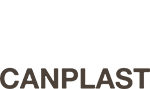

1. Tack welding is a necessary operation in order to obtain a good weld. This hot assembly operation, with no required additional material, makes it possible to plug the spaces between the elements and fix them slightly before welding them.

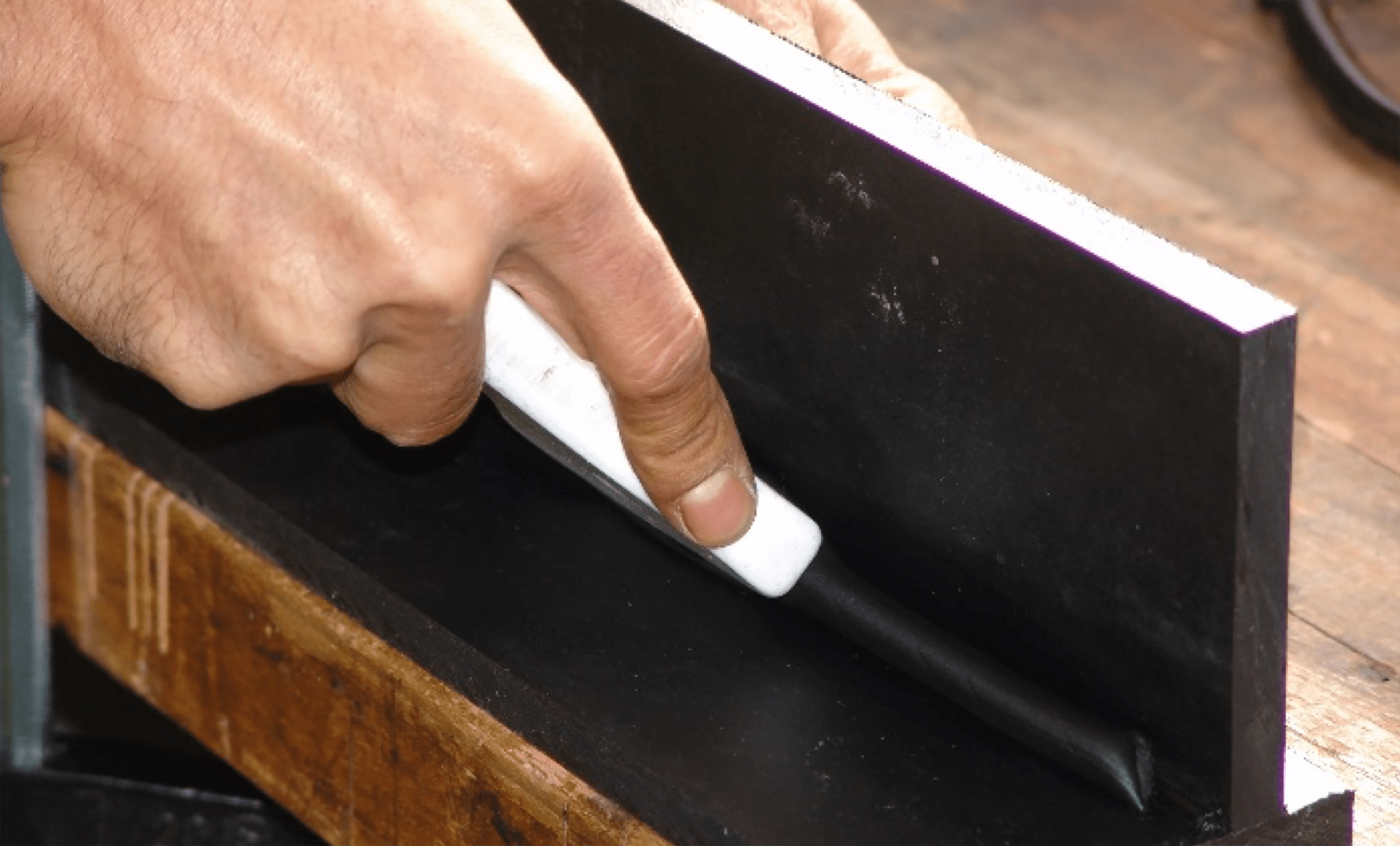

2. The welding is carried out with a suitable nozzle. The filler material is a triangular rod. The air at over 300°C produced by the device simultaneously heats the underside of the rod and the upper face of the support.

3. The pressure exerted on the rod and the welding nozzle is sufficient to obtain excellent adhesion of the welding nozzle. The orange or grey colour of the PVC does not disrupt the weld because it is the same material, simply with a different dye.

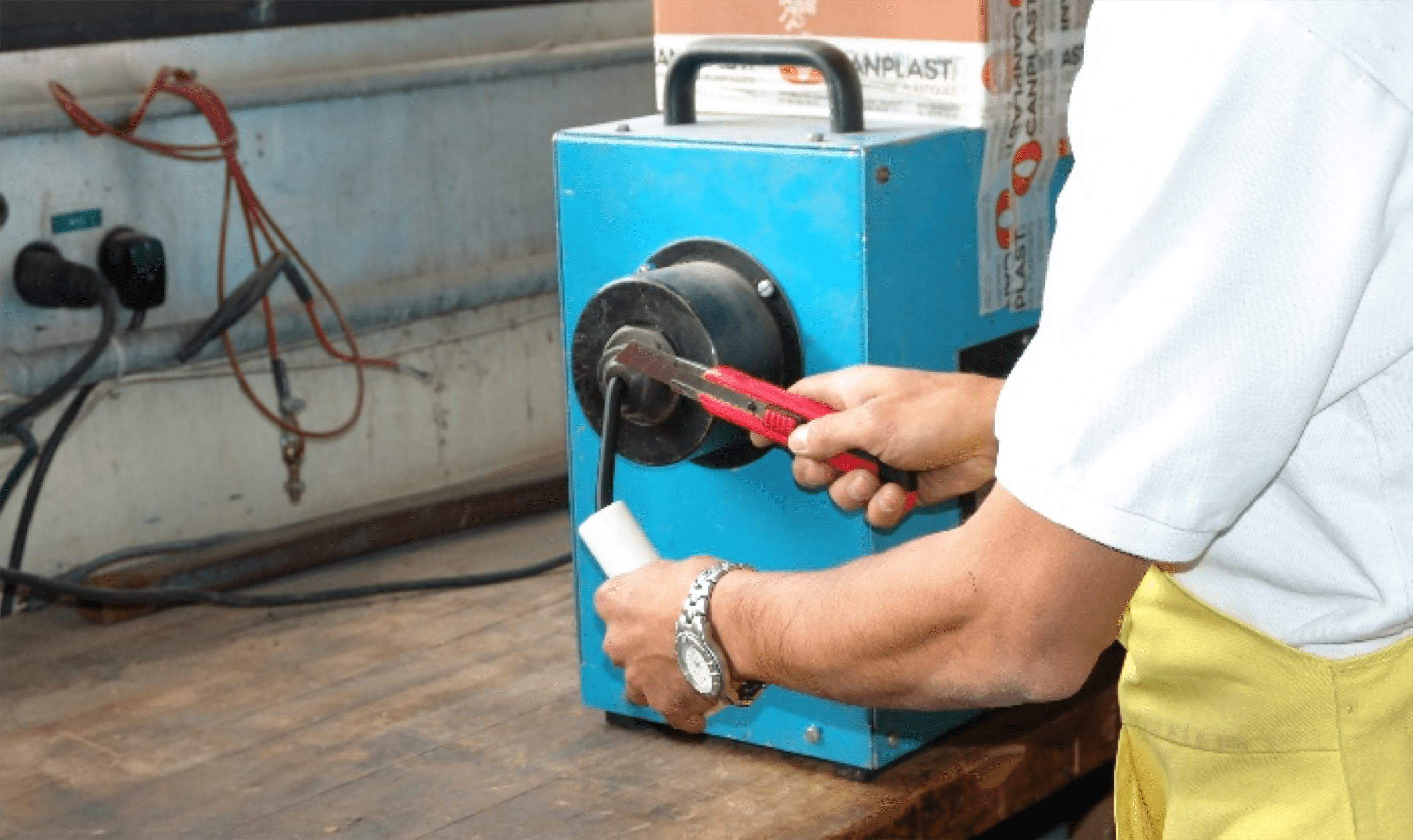

1. The raw material is in the form of granulated PE (polyethylene) which is used to fill the silo placed on the extruder.

2. The welder heats the tack welded elements with a blow-dryer. His experience allows him to test the temperature of the support by pressing a metal point on the material which softens through heating.

3. The extruder heats the filler material to a temperature of approximately 220°C and propels it into a sausage shape through a nozzle of variable diameter. The welder carries this weld bead inside a Teflon pipe and applies it unto the support.

4. For all types of plastic welds, it is important that the temperature of the support and the filler material are the same and that the contact pressure is maintained. For this, we crush the weld with a Teflon spatula.

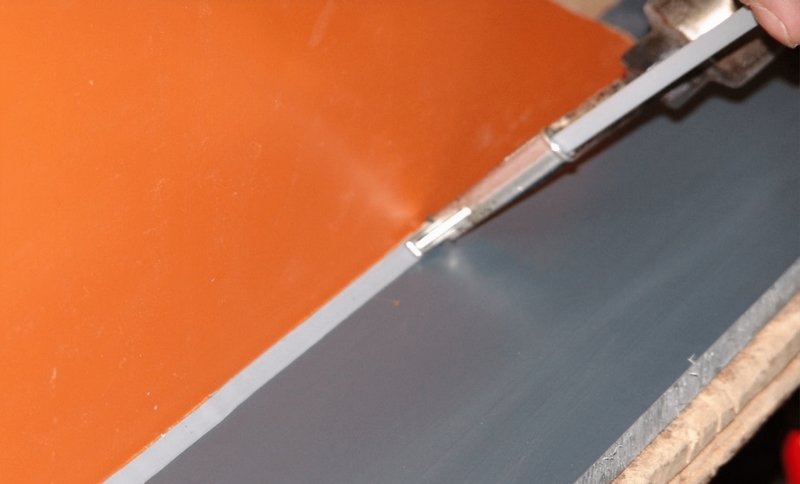

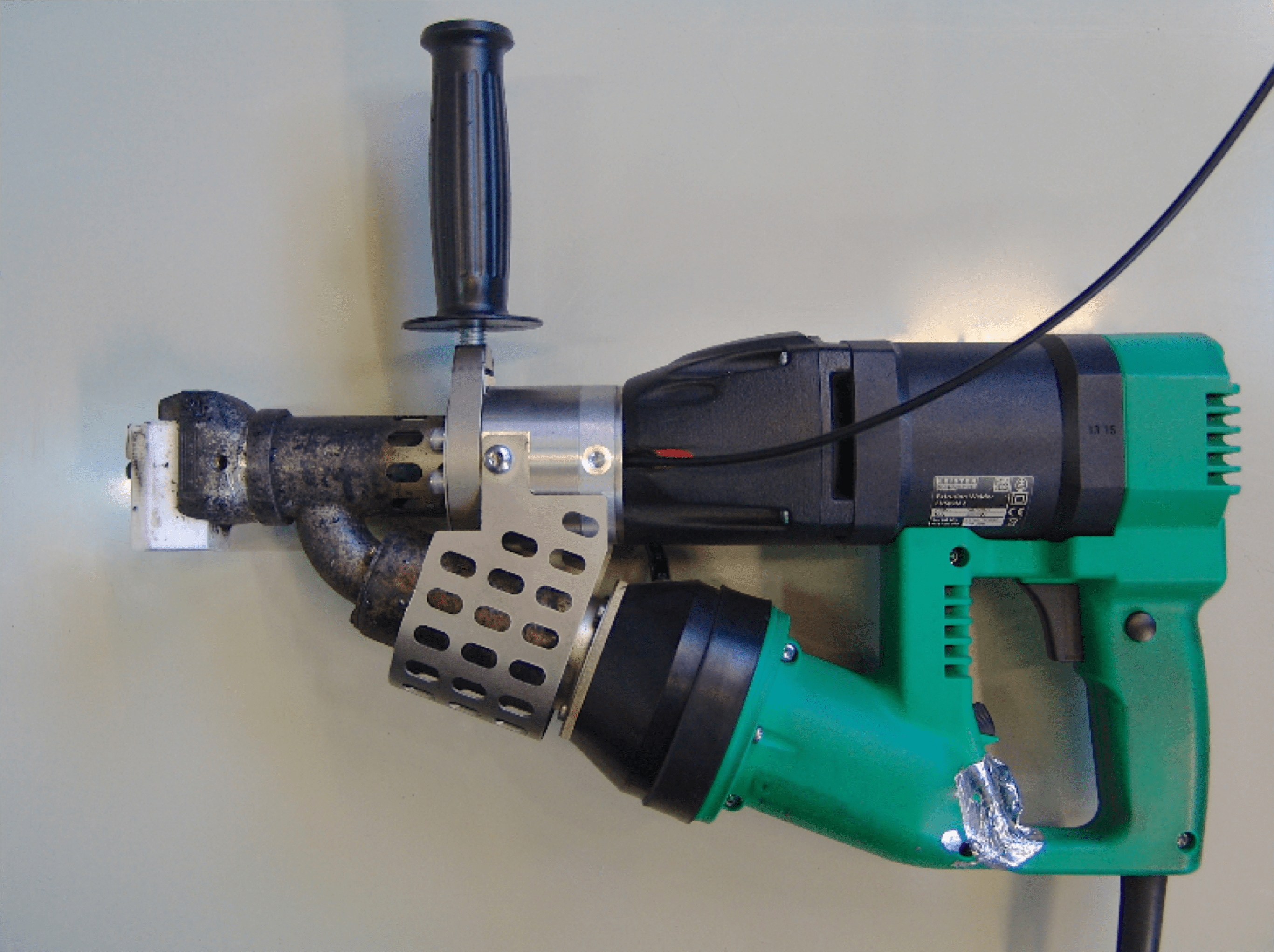

1. This gun-extruder is used for welding PE (polyethylene) and PP (polypropylene). It is fed with raw material through a wire of 4 or 5 mm in diameter. The material, heated between 200 and 220°C, is propelled through the apparatus by a worm drive. A similar device is especially designed for PVC welding.

2. Tack welding, described in 'PVC welding', is necessary for both PE and PP as well as for PVC. For PE and PP, surface scraping is required before welding.

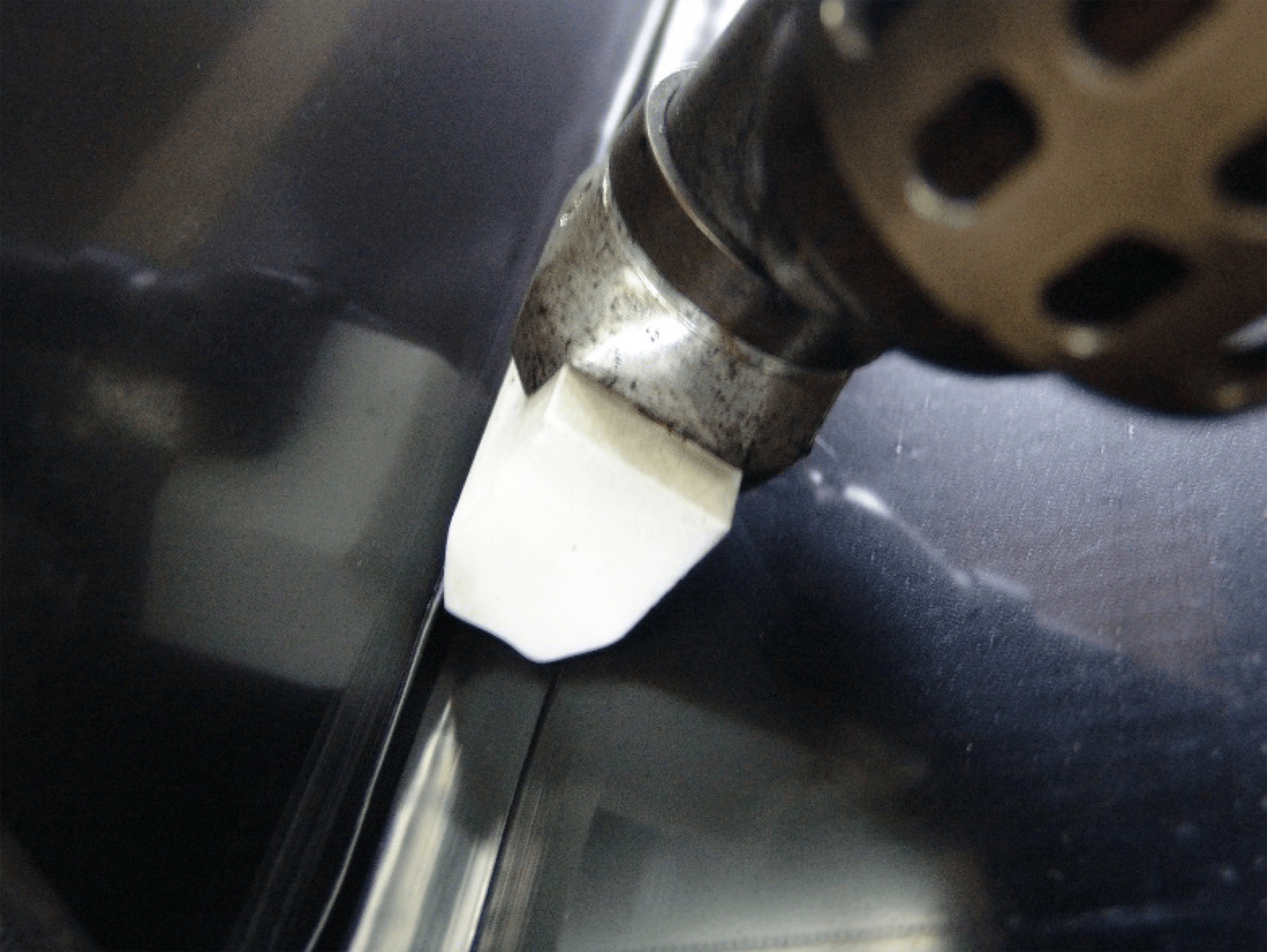

The elements to be welded are heated by a hot air nozzle located at the front of the tip of the gun. The Teflon shoe located at the rear of the gun tip is shaped according to the shape and size of the desired weld bead.

3. Welding of a PE chamber base with a gun-extruder. For welding in confined spaces, refer to « PE Welding with Haering© extruder »