- Which type of valve should we choose ?

- Canplast non-return valves

- Waback® non-return valves

- Wastop® backflow valves

Overview

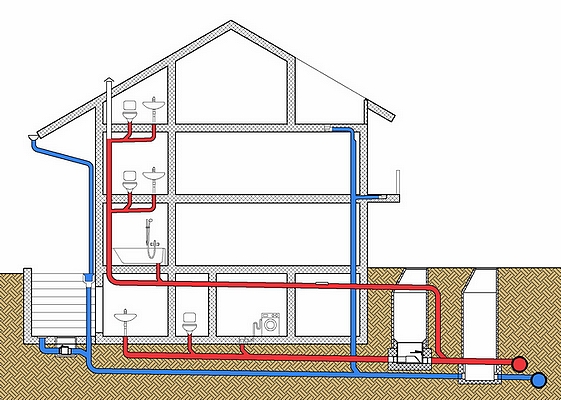

A backflow valve should be installed whenever there is a possibility of backflow. The backflow is due to a loading of the communal collector which can be caused by heavy storms. This phenomenon is often observed along unit collectors or near stormwater runoffs on separating collectors. Most often, the unfavourable situation is not known at the time of construction and the valve becomes a backup solution to prevent further flooding. The choice of the model of the valve is often dictated by the characteristics of the pipe and by the existing inspection chambers.

Operation of a valve

Ideally, the valve should be opened in order to allow normal flow and closed when there is backflow. In practice, operation is much simpler when discharging rainwater or solids-free wastewater from floor grills or sinks. The flow of water pushes a clapper that remains closed when there is no flow. For wastewater containing solids, systems that promote the passage of solids carried by water should be used.

|

Applications

|

Clapper valves

|

Valve without float

|

Float valves

|

Wastop® valves

|

Waback® valves

|

|

| Clean water, rainwater |

yes

|

yes

|

yes

|

yes

|

yes

|

|

| Solids-free wastewater |

yes

|

yes

|

yes

|

yes

|

yes

|

|

| Wastewater, containing solids |

no

|

no

|

yes

|

possible

|

yes

|

|

| Fixing in existing manhole |

Unlikely

|

possible

|

possible

|

yes

|

yes

|

|

| Fixing in new manhole |

possible

|

possible

|

possible

|

yes

|

yes

|

|

| Creation of a new manhole |

possible

|

possible

|

possible

|

Not necessary

|

possible

|

|

| Anti-odour on overflow |

no

|

yes

|

no

|

yes

|

no

|

|

| Low level variation |

yes

|

yes

|

no

|

yes

|

yes

|

|

| High level variation |

no

|

yes

|

necessary

|

yes

|

possible

|

|

| Collector Ø in mm |

110 to 315

|

110 to 400*

|

110 to 400*

|

75 to 1400

|

110 to 315

|

|

| Material used |

PVC

|

PVC

|

PVC

|

INOX

|

PE

|

|

| Price category in CHF |

From 290.-

|

From 585.-

|

From 665.-

|

From 830.-

|

From 1'710.-

|

|

|

|

|

|

|

||

|

* Other dimensions on request

|

||||||

Clapper non-return valves

Injected PVC with cleaning hatch

Area of use

This type of valve is inserted in the pipe system as a normal PVC short pipe. It can be put in place as a preventive measure during construction, or later, after having observed the presence of a backflow. If it is buried, it is necessary to put it at the bottom of a manhole in order to have access to it, control its operation and clean it. It is also useful to prevent some animals, such as rodents, from getting back into the pipe.

PVC non-return valves without float

Area of use

This type of valve can be installed in an existing or new inspection chamber. It is suitable for rainwater or wastewater that is free of solids. It can also be used as an anti-odour valve on overflow pipes. The difference in level between the lower level of the upstream pipe and the base of the inspection chamber must be at least 20 to 40 mm depending on the model. The valve must remain accessible for inspection or maintenance.

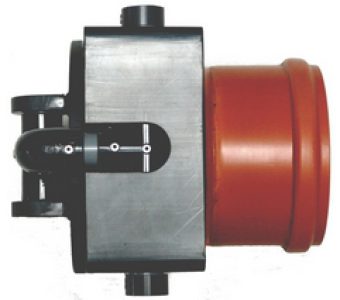

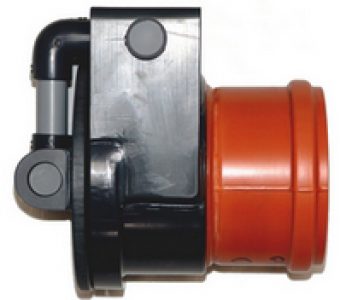

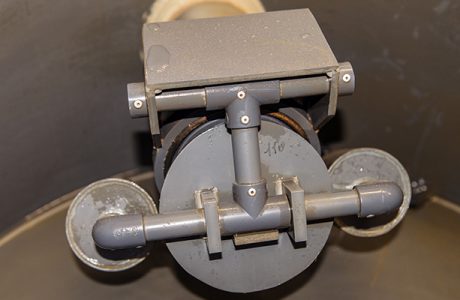

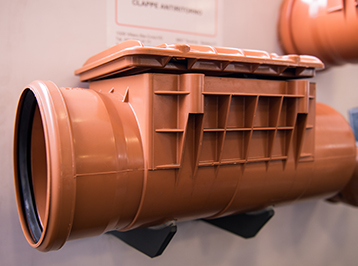

PVC non-return float valves

Area of use

The non-return valve prevents backflow of wastewater into basements when the communal collector or the collector of the residential area is loaded.

The Canplast PVC valve is designed for installation on plastic pipes, but it can also be adapted to other types of pipes. This type of valve can be installed in an existing or new inspection chamber. It is recommended for wastewater that contain solids. The difference in level between the lower level of the upstream pipe and the base of the inspection chamber must be sufficient to allow the floats to move. The valve must remain accessible for inspection or maintenance.

Operation

When the pipe runs normally, the weight of the floats keeps the damper open. When the water level rises in the collector, the floats rise and close the damper.

For proper operation, it is necessary that the movement of the floats not be hindered by a possible build-up of solid matters. The non-return valve should be cleaned regularly.

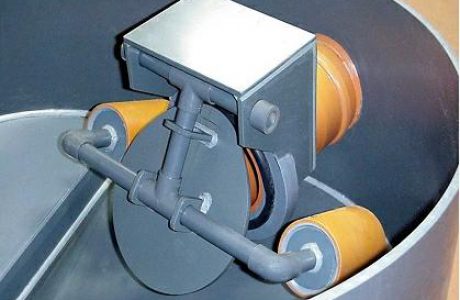

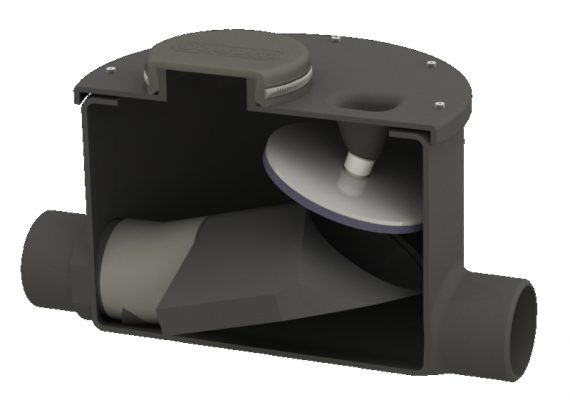

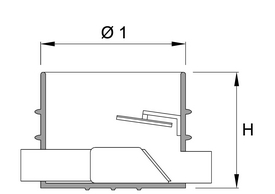

When to use a Waback® valve

WaBack® is a manhole that is installed outside buildings, on the wastewater outlet, where it plays the role of a backflow valve.

The installation of a Waback® on the wastewater outlet of the building offers a safe protection against the flooding of basements in the zones at risk.

WaBack® works both as a non-return valve and as a manhole. Installed during construction, this "all-in-one" module reduces installation costs.

Its small size allows it, in some cases, to be installed in existing concrete manholes of 80 cm diameter and over.

Wastewater is often very loaded with solids. In this context, Waback® is a safe choice. Its pipe is fully open at normal flow, which minimizes the risk of technical incidents and the need for maintenance operations.

The standard model of Waback® is prefabricated in polyethylene. It is quickly available from our stock.

WaBack® is also obtainable in "mini" version for cellar installation.

|

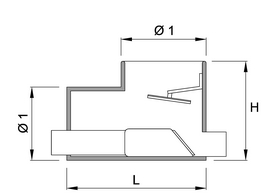

Reference

|

Pipe Ø

|

Ø1

(mm) |

H

(mm) |

L

(mm) |

|

wb110-mini

|

110

|

400

|

306 mm | |

|

wb110-600

|

110

|

720

|

580 mm

|

|

|

wb160-600

|

160

|

720

|

580 mm

|

|

|

wb200-600

|

200

|

720

|

575 mm

|

730

|

|

wb315-800

|

315

|

720

|

1200 mm

|

Tested and certified

WaBack® has been extensively tested and has been adopted in many countries. Since 1988, WaBack® has avoided thousands of potential floods !

Waback® backflow valves require minimal maintenance. WaBack® is CE certified for backflow protection in wastewater or rainwater systems.

Tips :

Keep in mind that every time the main collector fills up, the valve closes, and that when the valve is closed, it is not possible to evacuate water from the building. Therefore, it is advisable, when possible, to connect all wastewater pipes that comes from the higher levels or rainwater pipes that come from the roof downstream of the valve.

This measure prevents the wastewater from the floors coming out of the basement grills or the rainwater filling the drainages or overflowing by the grills located in the basement.

The WaBack® non-return valve and WaBack® Access has been thoroughly tested by both laboratories and councils in Sweden, Norway and Denmark. All tests show that all WaBack® models are effective in stopping flooding caused by backflow and that it requires minimal maintenance. WaBack® and WaBack® Access are certified for use in storm water and sewage systems. The entire WaBack® range is CE approved according to regulations for building products. WaBack® check valves are for use as a non-return valve of Type 1 for back flow in sewage and drainage systems. SS-EN-13564-1:2002.

Security alarm

If the water from the upper floors cannot be separated from the basement water, it is recommended to install a level alarm that will warn you of the closure of the valve and of the risk of a small flood due to the waters coming from your own building.

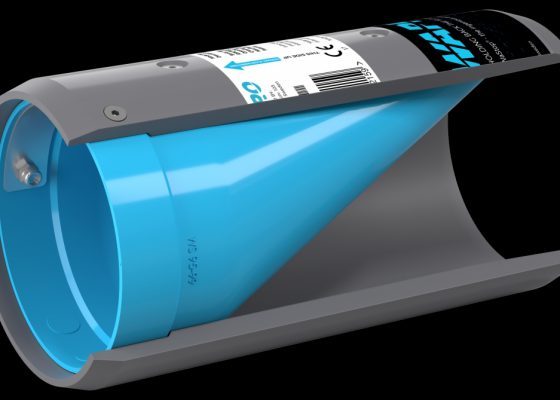

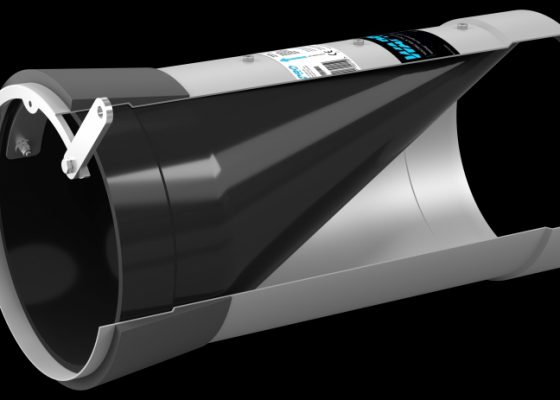

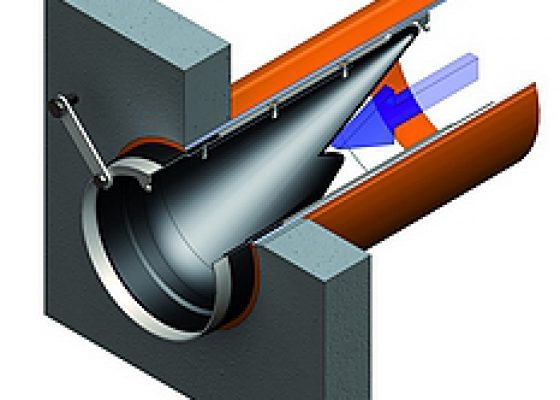

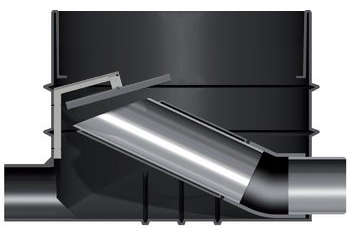

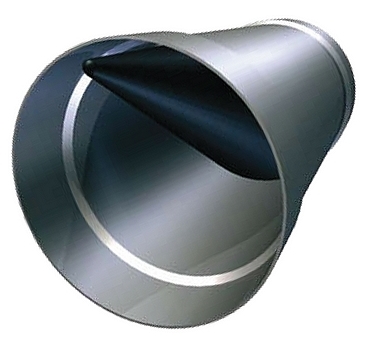

The Wastop® valve consists of a stainless steel or plastic cylinder with a conical polyurethane membrane attached inside.

The Wastop® valve:

- is the only valve that can be installed easily and at no additional cost in an existing inspection chamber or along an accessible pipe,

- is the only one that can be installed on both low gradients and vertical columns,

- can be installed in all pipes of circular section whatever the material,

- can be installed in all pipes from Ø 75 mm to Ø 1'785 mm,

- prevents backflow. It also has the advantage of preventing odours from rising in the building.

|

|

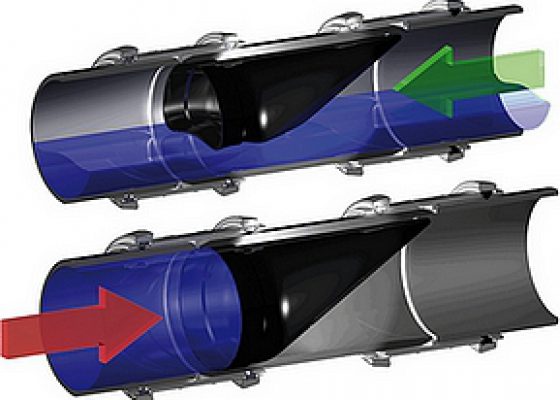

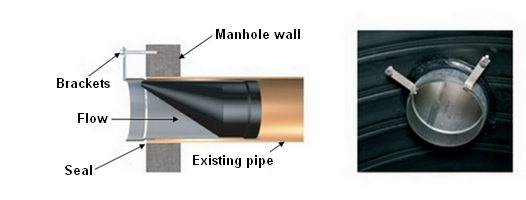

| Flow in the right direction causes the membrane to rise and allows water to flow (Fig.1). | If the flow is reversed (backflow), the conical membrane fills up and projects against the wall of the pipe, preventing any flow in the wrong direction (fig.2). |

The Wastop® valve can be installed in a few minutes inside an existing manhole. It can be placed upstream or downstream of a manhole located outside the building (fig.3). The seals and the brackets are delivered with the valve.

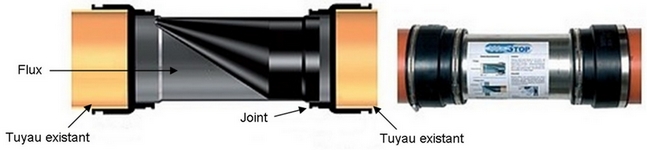

The Wastop® valve is inserted in a pipe and connected using two sleeves (fig.4)

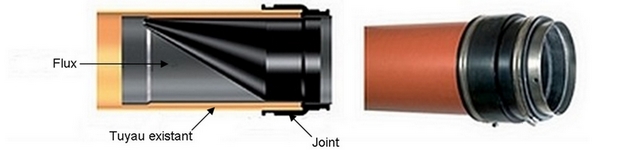

or pushed in place at the end of a pipe (fig.5).

Stainless steel version 304/316

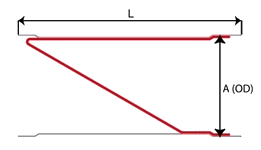

|

Reference

|

DN

|

Weight

(kg) |

A

(mm) |

L

(mm) |

Int. Ø of existing pipe

(min.-max.) |

|

ws97std

|

100

|

0.700

|

97

|

210

|

99-101

|

|

ws101std

|

110

|

0.800

|

100

|

215

|

101-104

|

|

ws116std

|

125

|

0.900

|

115

|

230

|

117-120

|

|

ws146std

|

150

|

2.400

|

144.5

|

300

|

146-159

|

|

ws183std

|

200

|

4.200

|

181

|

385

|

182-200

|

|

ws193std

|

200

|

4.600

|

191

|

395

|

193-210

|

|

ws215std

|

225

|

5.500

|

215

|

450

|

216-233

|

|

ws230std

|

250

|

6.200

|

230

|

480

|

232-248

|

|

ws240std

|

250

|

6.700

|

240

|

520

|

242-258

|

|

ws283std

|

300

|

10.000

|

283

|

600

|

286-300

|

|

ws290std

|

300

|

10.000

|

290

|

600

|

293-307

|

|

ws340std

|

350

|

18.000

|

340

|

700

|

343-349

|

|

ws370std

|

400

|

20.000

|

370

|

730

|

373-391

|

|

ws390std

|

400

|

24.000

|

390

|

750

|

393-411

|

|

ws440std

|

450

|

28.000

|

443

|

840

|

446-464

|

|

ws490std

|

500

|

29.000

|

490

|

900

|

493-503

|

|

ws590std

|

600

|

48.000

|

587

|

1200

|

590-598

|

|

ws690std

|

700

|

63.000

|

690

|

1300

|

695-705

|

|

ws750std

|

750

|

75.000

|

750

|

1400

|

755-765

|

|

ws790std

|

800

|

88.000

|

790

|

1500

|

795-805

|

|

ws885std

|

900

|

116.000

|

885

|

1700

|

890-910

|

|

ws985std

|

1000

|

141.000

|

985

|

1800

|

990-1010

|

|

ws1185std

|

1200

|

290.000

|

1185

|

2250

|

1190- 1210

|

Plastic version

|

Reference

|

DN

(mm) |

Weight

(kg) |

A

(mm) |

L

(mm) |

|

ws75pvc

|

75

|

0.300

|

75

|

125

|

|

ws110pvc

|

110

|

0.900

|

110

|

210

|

|

ws125pvc

|

125

|

1.200

|

125

|

240

|

|

ws160pvc

|

160

|

2.100

|

160

|

310

|

|

ws200pvc

|

200

|

4.100

|

200

|

400

|

|

ws250pe

|

250

|

6.300

|

250

|

480

|

|

ws250pe-I

|

250

|

4.600

|

236

|

480

|

|

ws315pe

|

315

|

12.500

|

315

|

600

|

|

ws315pe-I

|

315

|

8.300

|

295

|

600

|

For other diameters, please contact Canplast.

Non-contractual data

Used on a rainwater system, the cleaning requirements of the Wastop® valve are practically non-existent.

For use on pipes for wastewater containing solids, in an existing chamber, with a gradient of less than 3%, checks and possible cleaning will be needed.

For the evacuation of wastewater in a chamber that has yet to be built, it is advisable to install a Waback® type valve or a culvert valve.

Ø 75 to 200 mm models were tested for a return pressure of 5 meters of water column. The other dimensions are tested for a pressure of 3 meters of water column.

A rigorous testing procedure is undertaken at Wapro® to ensure our valves meet our exacting standards. Our valves tested to appropriate standards in our target markets at third party organizations such as Utah State University Hydraulics Lab, Danish Technological Institute. Kiwa Sverige AB on an annual basis.

CE-approved models type 0 (NPS 3-8") are tested according to SS-EN 13564-2:2002.

WaStop® also meets the requirements according SS-EN 13564-1:2002 and quality assurance according SS-EN 13564-3:2004. Other dimensions are tested according to the same standard and meets the same requirements and quality assurance.

WaStop is patented in the EU, USA and other countries.

Wastop Residential

Wastop Inline

Wastop® has a wide scope of application: from protection against flood of basements (fig.6) to rising levels of lakes (fig.7).