- Properties of plastics

- Behaviour and resistance

- Standardisation

- Assembly

- Implementation

- Ecology

- The common installation errors to be avoided

Canplast marketed PVC pipes in 1964, PE pipes in 1980 and PP pipes in 2005.

Raw materials

Polyethylene (PE) and polypropylene (PP) are produced from petroleum derivatives.

PVC is produced from salt (57%) as well as petroleum derivatives (43%). PVC is therefore more economical in fossil resources.

Volumetric mass density

Average values:

| PVC: 1'400 kg/m3 | PE: 950 kg/m3 | PP-HM: 900 kg/m3 |

Modulus of elasticity

PVC has the best long-term behaviour.

| PE | PP | PVC | |

| Modulus of elasticity (value for 1 min) |

1'000 N/mm2 | 1'250 N/mm2 1'700 N/mm2 * 2'800 N/mm2 ** |

3'000 N/mm2 |

| Modulus of elasticity (long-term value) |

250 N/mm2 | 300 N/mm2 425 N/mm2 * 700 N/mm2 ** |

1'500 N/mm2 |

| Variation (%) Long-term/short term |

75% loss | 75% loss | 50% loss |

* for PP pipes with high modulus of elasticity (PP-HM)

** for multi-layer pipes reinforced with mineral substances

Roughness

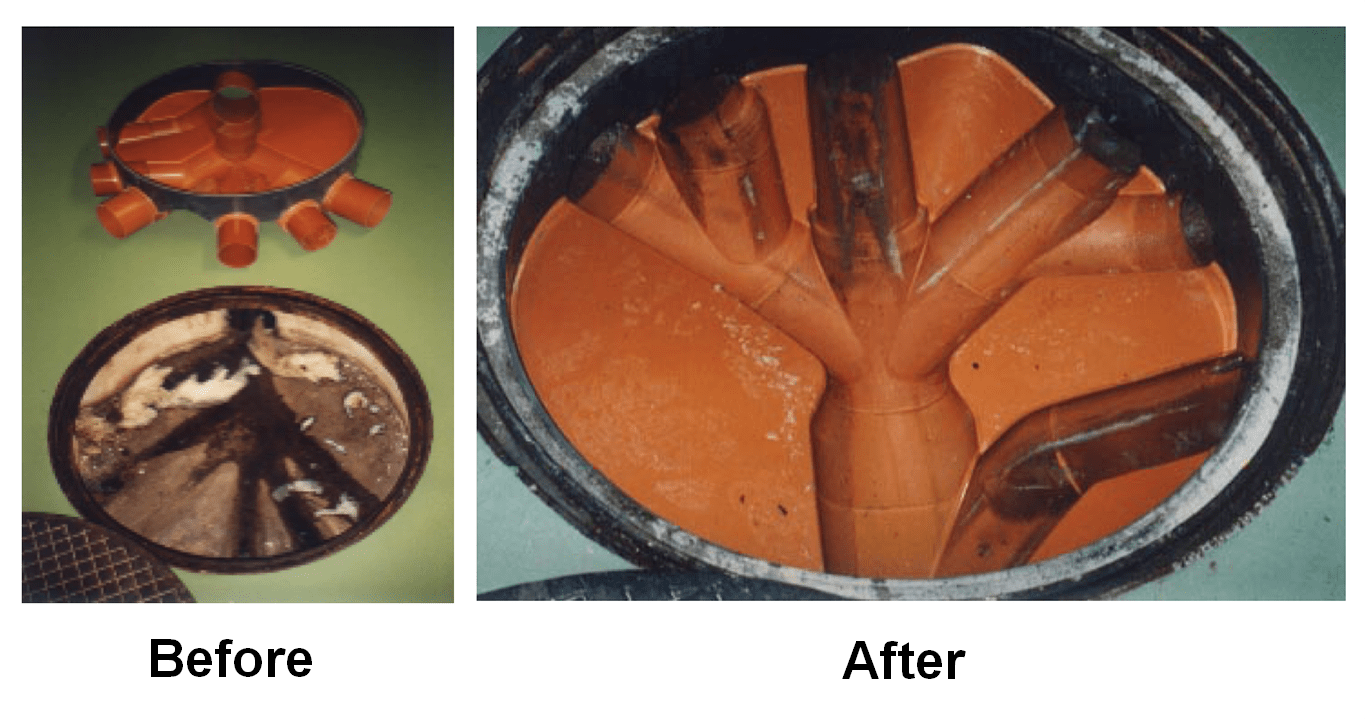

PVC, PP and PE pipes have a very low roughness. It is important that manholes have the same qualities as pipes. This avoids the accumulation of deposits, reduces maintenance costs and facilitates cleaning. Our many years of experience help us ensure that the quality of internal surfaces of the pipes remains unchanged.

Temperature of operation

As long as mechanical stresses are not excessive, the plastic pipes resist non-continuous use at the following temperatures:

| PVC: 40 °C | PE: 60 °C | PP: 80 °C |

Thermal expansion coefficients

Average values:

| PVC: 0,08 mm/m.°K | PE: 0,2 mm/m.°K | PP: 0,14 mm/m.°K |

The thermal expansion coefficients above indicate by how many millimeters a 1-meter-long pipe will lengthen or shorten when the temperature varies by plus or minus 1 degree Celsius or Kelvin.

When laying aerial plastic pipes, it is very important to take into account the expansion and positioning of the fixed points.

For buried M/F fitted pipes, we must not neglect the effects of the sun and temperature variations between day and night, in particular for PE.

Fire resistance

Hard PVC can burn but does not easily burn. During a fire, PVC releases hydrochloric gas. It is recommended to use PVC pipes in buried or concrete-encased areas. PE and PP are flammable.

Deformation under loads

The behaviour of PVC pipes in response to load is very good. For this material, it is not necessary to reinforce the structure with stainless steel rings when installing Straub® or Wall Collar system sealing joints.

The behaviour of PE pipes in response to load is poor. For this material, it is necessary to reinforce the structure with stainless steel rings when installing Straub® or Wall Collar system sealing joints.

The behaviour of PP-HM pipes in response to load is medium. For this material, it is recommended to reinforce the structure with stainless steel rings when installing Straub® or Wall Collar system sealing joints, on pipes of low rigidity.

Deformation at the extremities

During the extrusion of a pipe, and more particularly during its cooling, internal tensions are created in the material of the pipe. When cutting a pipe, the diameter decreases at its end. This phenomenon is very important for polyethylene, moderate for high modulus polypropylene and small for PVC. Precautions should be taken for PE and PP-HM when installing Straub© fittings.

Impact resistance

In general, the PVC, PP and PE pipes have an impact resistance which diminishes as the temperature decreases. PE is the product that is most resistant to impacts, followed by PP and compact PVC.

Structured PVC is much more fragile than compact PVC. For details, see "PVC pipes with M/F fitting and rubber seal".

Chemical resistance

PVC, PP and PE pipes have a good chemical resistance. They are very appreciated for wastewater networks. For special cases with industrial water, it is necessary to know the nature of the liquids transported as well as their concentration and temperature. The chemical resistance of the joints must also be taken into account.

UV resistance

PE pipes are the most resistant to UV, provided they are black in colour. PE pipes of other colours are less resistant to UV.

PVC pipes whiten when exposed to sunlight. The colouring of PVC pipes is attacked by UV rays. This phenomenon is very superficial; it does not influence the resistance of the pipe.

European standards (EN)

The main standards for PVC, PP and PE pipe are as follows :

SN EN 1401: Compact PVC for non-pressure underground collector

SN EN 1852: Compact PP for non-pressure underground collector

SN EN 12666: Compact PE for non-pressure underground collector

SN EN 13476: Structured PVC, PP and PE for non-pressure underground collector

Rigidity class

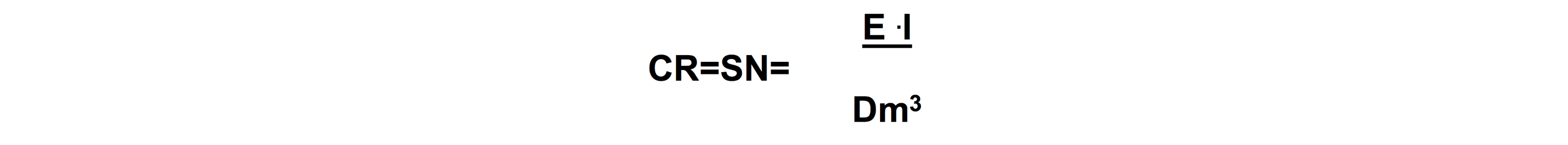

The annular stiffness class SN (formerly CR) is a function of the modulus of elasticity of the material, the inertia of the wall of the pipe, as well as the average diameter of the pipe. The rigidity is expressed in kN/m2

The most common rigidities are :

PVC: SN 2, SN 4, SN 8 and SN 0,5 for certain large diameters to be encased in concrete.

PE: SN 2, SN 4, SN 8

PP: SN 4, SN 8, SN 12, SN 16

If you need more rigid pipes, you can use “pressure” pipes.

The choice of rigidity is made according to recovery height and the traffic loads.

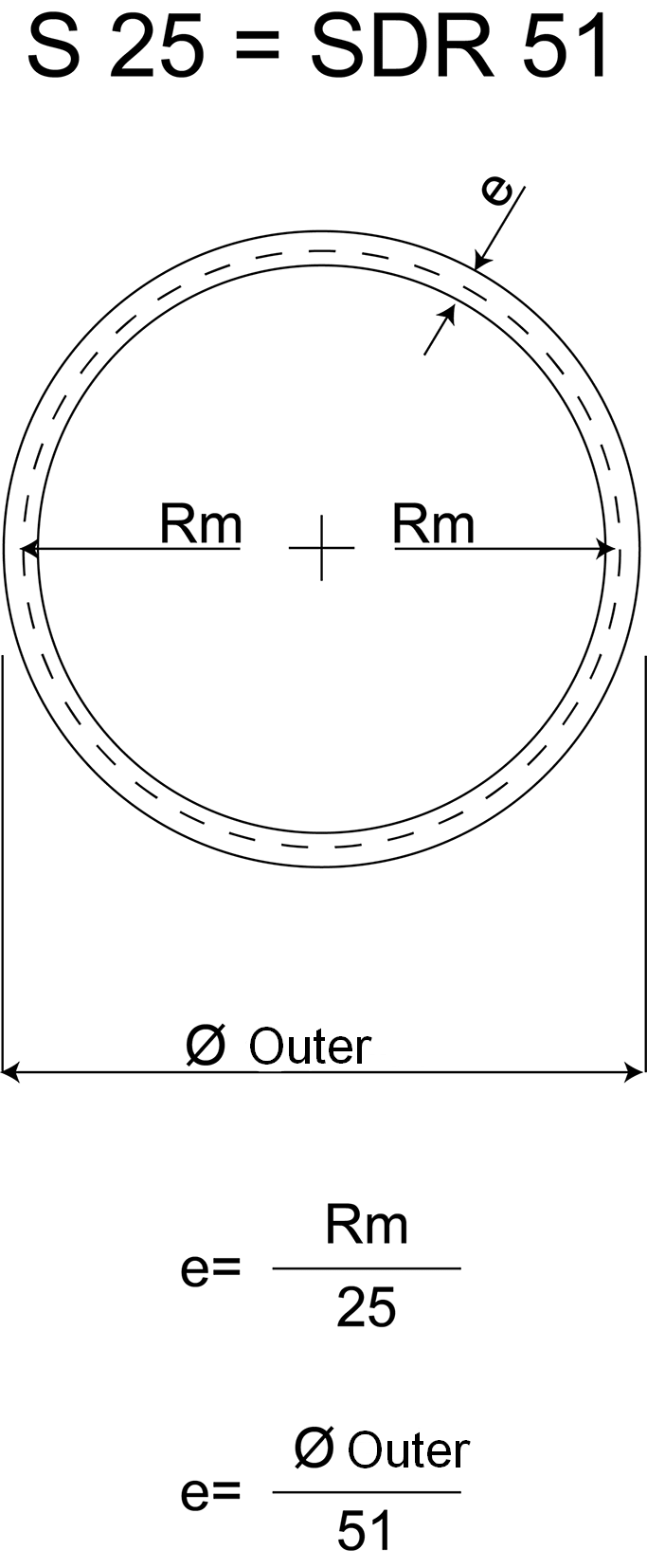

Pipe series

The theory is valid for all types of plastic pipes

Example : PVC SN 2

Old standardisation with "S25" designation. The old standard expressed the relationship between the average radius and the thickness of the pipe wall.

New standardisation with "SDR 51" designation. The current standard expresses the relationship between the outer diameter and the thickness of the pipe wall.

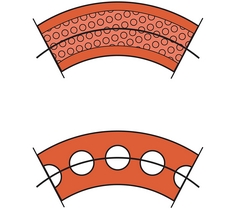

Differences between compact pipes and structured pipes

The standards governing compact pipes are more stringent than those governing structured pipes, especially for impact resistance. This means that the quality of the compact pipes is much higher than that of the structured pipes.

EN 13476 covers all structured PVC, PE and PP pipes. In this category of pipes, the goal is to save material, without reducing the inertia of the pipe wall. Warning ! According to EN 13476, the ring stiffness cannot be lower than SN 4. In Switzerland, many structured PVC pipes are sold with SN2 rigidity, which is sub-standard.

For PVC pipes, the economy can be realized in two different ways. The most common is to produce a three-layer pipe with a PVC foam core. The other method is to create longitudinal cells.

For PE and PP pipes, the economy is often achieved by a hollow annular structure. The inside of the pipe is smooth. The outer face of the pipe is corrugated or smooth, depending on the manufacturing method.

Warning ! The corrugated pipes are manufactured according to two different standards. DN-OD means that the nominal Ø corresponds to the outer Ø. DN-ID means that the nominal Ø corresponds to the inner Ø. Due to the large thickness of the pipe wall, hydraulic section variation is important.

Bonding assembly

Only PVC is designed to make bonded joints.

The contact area must be sufficient in order to ensure a good result. It must be clean and dry.

Bonding is difficult to achieve at low temperatures or in the presence of high humidity.

Welded joints

Only materials of the same type can be assembled by welding. For example, it is not possible to weld a PVC element to PE. The colour of the material is not an obstacle for the quality of the weld.

In order to weld the various plastics, it is essential to protect the welding element from rain, frost and wind, if the latter is too strong or cold.

Welding types

There are several types of welds. Among the many techniques available, the most commonly used in the field of construction are:

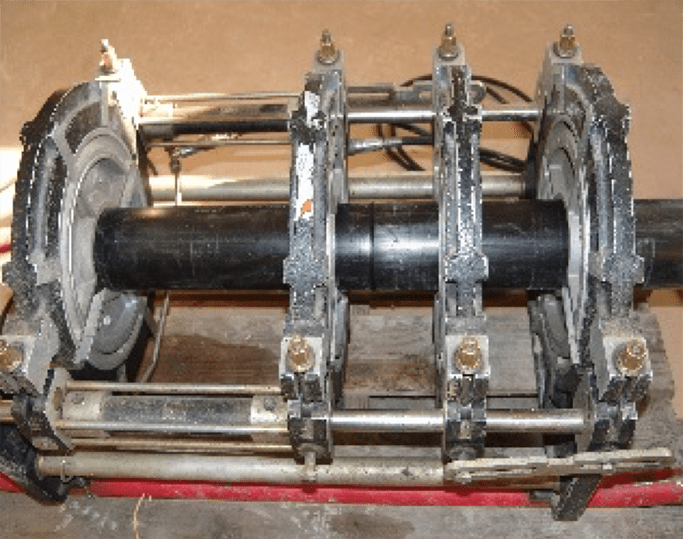

- Mirror welding, also called polyfusion or end-to-end welding.

- Electroweldable sleeve welding.

- Hot air welding by adding material.

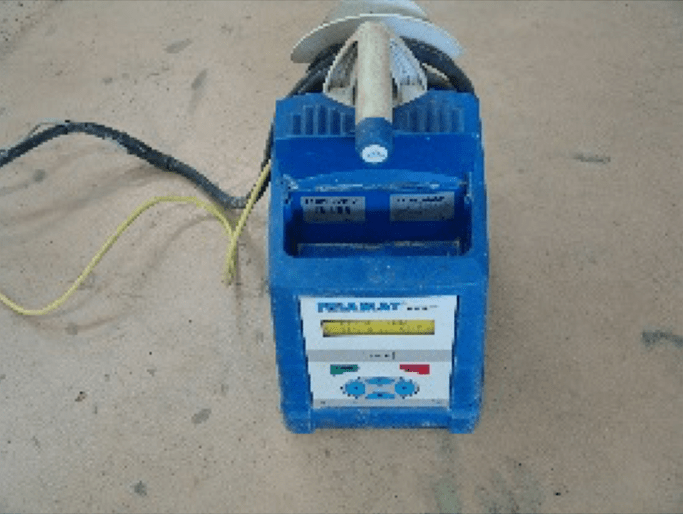

Mirror welding is widely used to join PE and PP pipes. This technique must be performed by qualified personnel. The welding machine is relatively bulky, it can be used in excavations or at the edge of the excavation. This process is especially interesting if the number of welds is important.

Although it is not standardised for PVC, this welding technique gives excellent results for specific applications carried out in the manufacture workshop.

Be aware that this welding method creates a small bead inside and outside the pipeline.

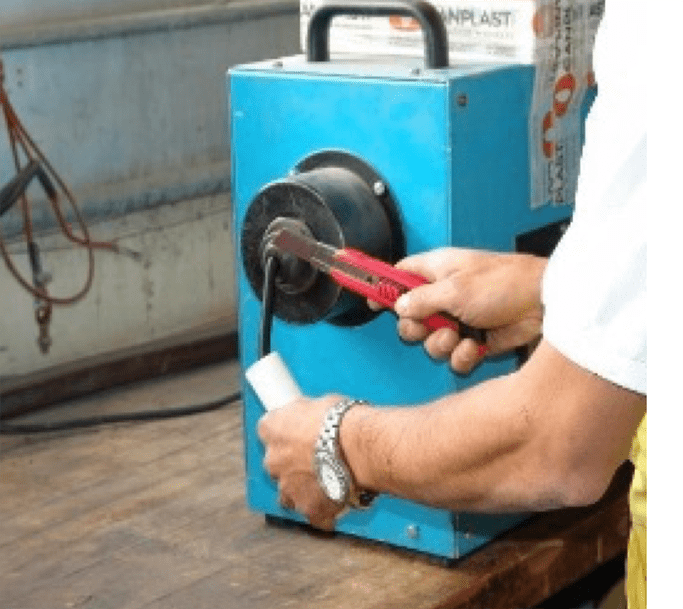

Electro-weldable sleeve welding is widely used to assemble PE pipes, whereas it is less common for PP pipes. This technique must be performed by qualified personnel. Many working phases are more difficult to master as part of this technique in comparison to mirror welding including scraping, cleanliness, ovality, scratches on the surface of the pipe, humidity, tolerance of dimensions, regularity of the energy source as well as voltages during welding.

The welding machine is compact; it can be used in excavations or for ceilings. Among other applications, this method is interesting for assembling prefabricated elements.

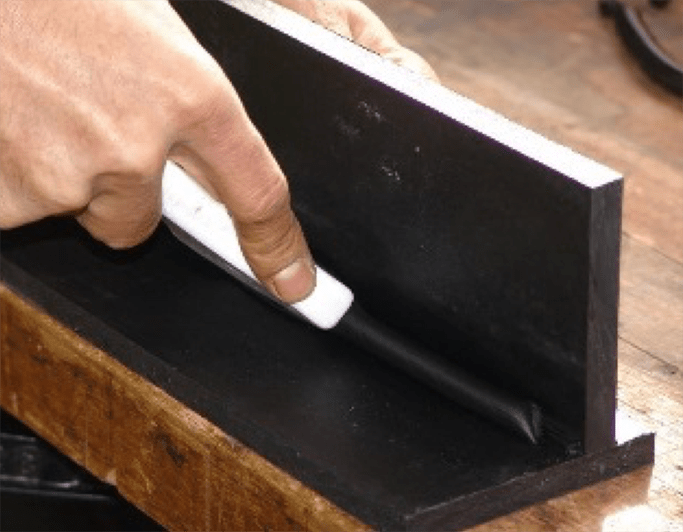

Hot air welding by adding material is mainly used in plastic boiler workshops. This technique also allows for on site repairs.

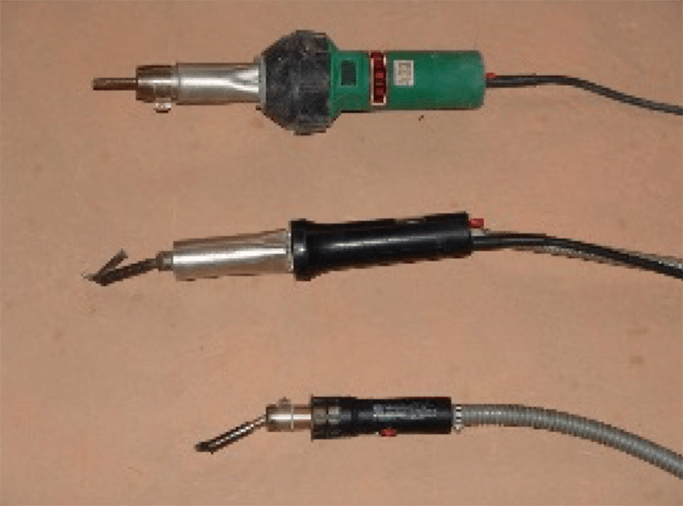

This type of equipment makes it possible to weld PVC, PE, and PP, among other materials. The filler material comes in triangular or circular rods.

This type of extruder makes it possible to weld, among other materials, PE and PP. The filler material comes in granules. This system allows you to choose the width of the weld seam and access confined areas.

This type of gun-extruder makes it possible to weld, among other materials, PE, PP and PVC. The filler material comes in circular section wire. This system allows you to choose the width of the weld bead.

See also " Canplast welds "

Welding tests

Welds can be tested in different ways :

The water test consists of filling the manhole or tank with water and checking the tightness of the structure.

The pressure test is used to check the tightness and resistance of elements intended for gas distribution and drinking water.

The electric arc test can detect even the smallest defects. For this test, a metal element must be placed on the opposite side or inside the weld seam.

Encasement of pipes

Encasement is done according to the requirements and standards in application. European standards concern only encasement with sand and gravel.

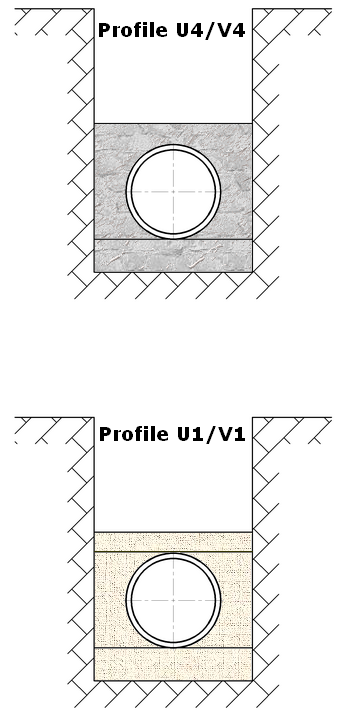

The SIA 190 standard offers two types of encasement :

- with gravel, profile U1/V1

- with concrete, profile U4/V4

Encasing the pipe with concrete is necessary in the following cases :

- When the calculation of deformations according to SIA 190 exceeds the authorised 5%.

- When required by SN 592000 in the private sector.

- When recovery is low and there is a risk of heavy traffic loads

Encasing the pipe with concrete is recommended in the following cases :

- When the slope of the pipeline is low, for example, less than 2%

- When the slope of the pipeline is high, for example, less than 10%.

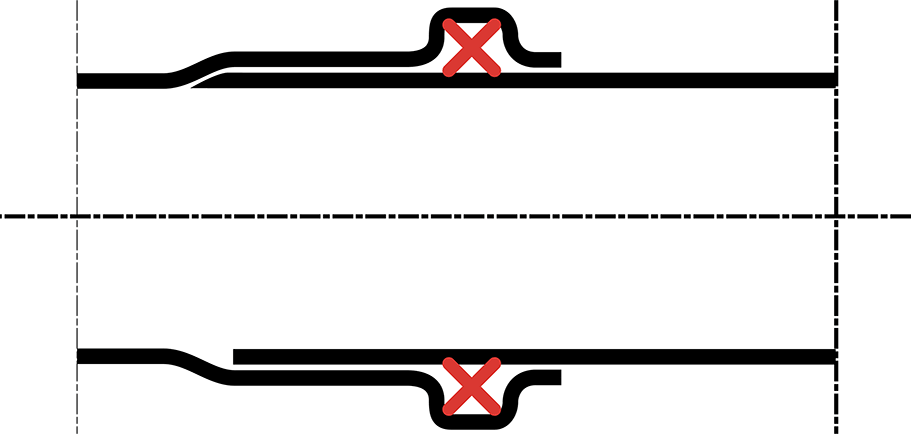

Warning ! The SIA 190 standard does not provide for partially concrete-encased plastic pipes. The bedding, which allows the bottom of the excavation to be well adjusted, must not be made of concrete with the rest of the gravel encasement. The plastic pipe cannot rest on a hard point.

Importance of the encasement quality

Encasing the pipe with gritty materials requires special care :

- It is recommended to use materials that are easy to set up and compact.

- The excavation must be wide enough to allow good lateral compaction.

- The width of the excavation depends on the diameter of the pipe.

- To ensure good compaction, it is important to work in layers.

- The more rigid the pipe, the less likely it will deform during installation.

- The quality of compaction has a strong impact on the future deformation of the pipe.

- The choice of a pipe with a higher-rated rigidity factor is not a guarantee against deformation. The quality of the installation has more influence on the deformation than the nominal rigidity of the pipe. Example: at equal depth and at equal traffic loads, a well-embedded SN 2 pipe deforms less than an SN 8 pipe with a medium-quality encasement. The calculation of deformations according to SIA 190 highlights the importance of a good implementation.

The above table corresponds to a recovery height of 2.5 m with 1 + 2 + 3 traffic loads, according to SIA 160

Eco-Devis / Eco Bau

Since the CRB (Swiss Research Centre for Rationalization in Building and Civil Engineering) has created a classification system for materials according to ecology, polyethylene and polypropylene are very well ranked. A new reality that few practitioners know is the excellent position of the "new" PVC. Indeed, the replacement of lead stabilisation with calcium and zinc stearates or organic materials has changed the image of PVC. Since lead stabilisation has been discontinued, PVC has been classified as a highly recommended product. See also "Compact PVC pipes, environment-friendly ".

Recycling

Through the activity of its manufacture workshops, Canplast produces more than 70 tons of wastes per year. The plastics are sorted, cut into pieces and crushed. After various treatments these materials are reintroduced into new fabrications. See also " Recycling plastic material ".

Before going into a detailed presentation of the errors, we recommend that you carefully read the EN 1610 standard which deals with the implementation of sanitation collectors. This standard defines, among other things, the storage of pipes, the excavation width, the thickness of the bedding, the height of the compaction layers, the quality of the encasing materials, the quality of the compaction, as well as tightness control.

Seals

With the exception of corrugated pipes, the SN 2, SN 4 SN 8 PVC, PE or PP pipe series are all compatible. It is important not to mix joints of different sizes or manufacturers. Each seal fits only a particular sealing groove. It is not possible to guarantee tightness in the absence of a sealing joint, even if the pipe is encased in concrete.

Lubrication of joints

It is recommended to use the lubricant supplied by the pipe manufacturer. Products based on mineral greases should not be used in any case. These products can cause damage to neoprene joints and make them porous.

If the worker does not have a lubricant, he can use soft soap or liquid soap.

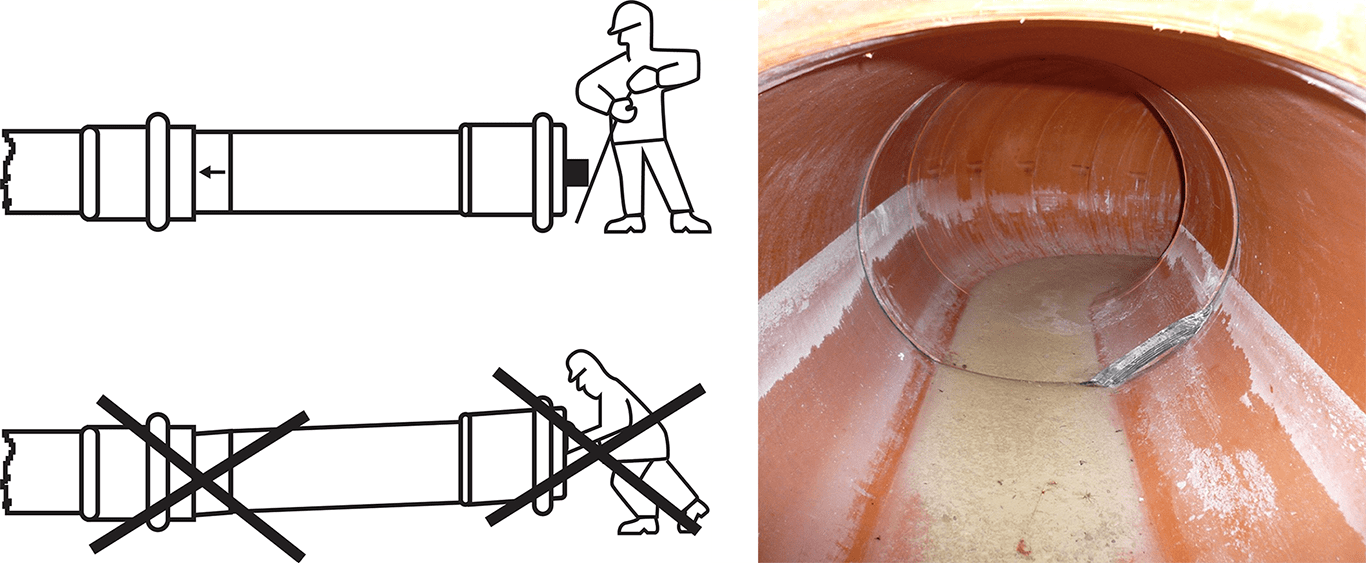

M/F Fitting

When connecting pipes or special parts such as elbows and branch lines, it is important that the thrust be exerted on the pipe axis. Any oblique fitting may cause the seal to come out of its groove.

When laying, it is recommended to visually assess that the sealing joint is in place. Finding and repairing a leak is very expensive.

Setting up the bottom of the excavation

Areas where the bottom of the excavation has been reworked will need to be appropriately treated in order to restore initial load bearing capacity. The slope adjustment is very important when the slope is low. The wooden adjustment wedges allow the precise realisation of the bedding. These wedges must imperatively be removed after adjustment and replaced by a supply of material identical to that of the bedding.

The abandonment of the wedges at the bottom of the excavation causes a hard point under the pipe, which will punctually deform the pipe. This deformation can increase over time because the wood will swell with the moisture from the ground.

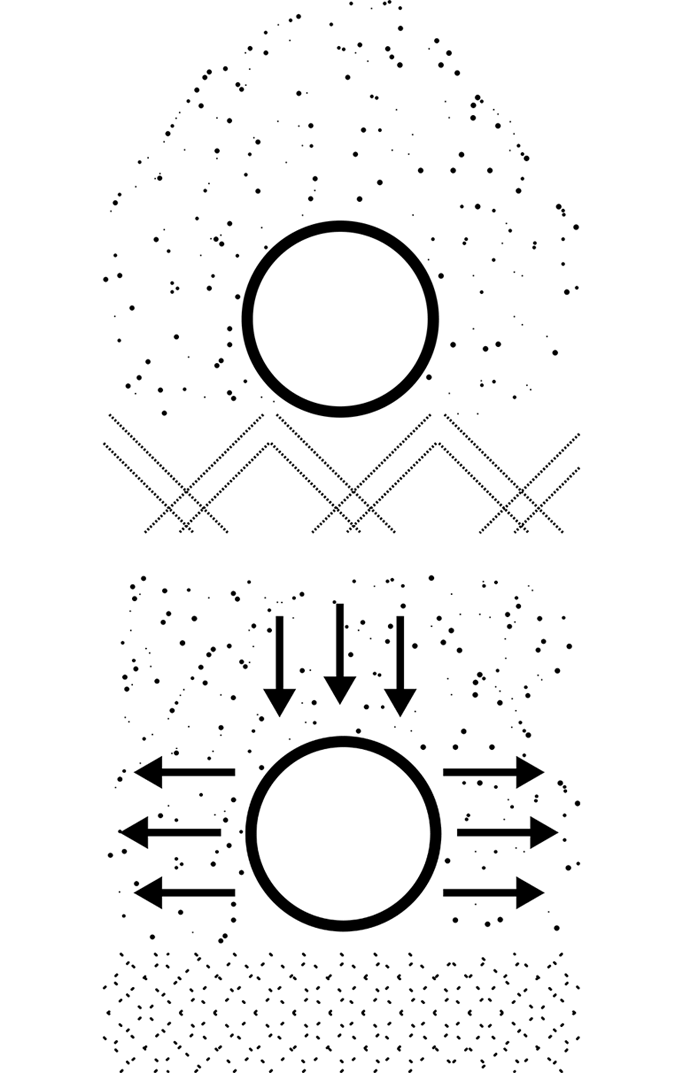

Positioning of the encasement

The pipe must be wedged and possibly ballasted in order to avoid any horizontal or vertical displacement.

Compaction on both sides of the pipe is essential in order to limit the future deformation of the pipe under traffic loads.

Unloading too much gritty material on the pipe or compacting too quickly can cause a very important initial deformation.

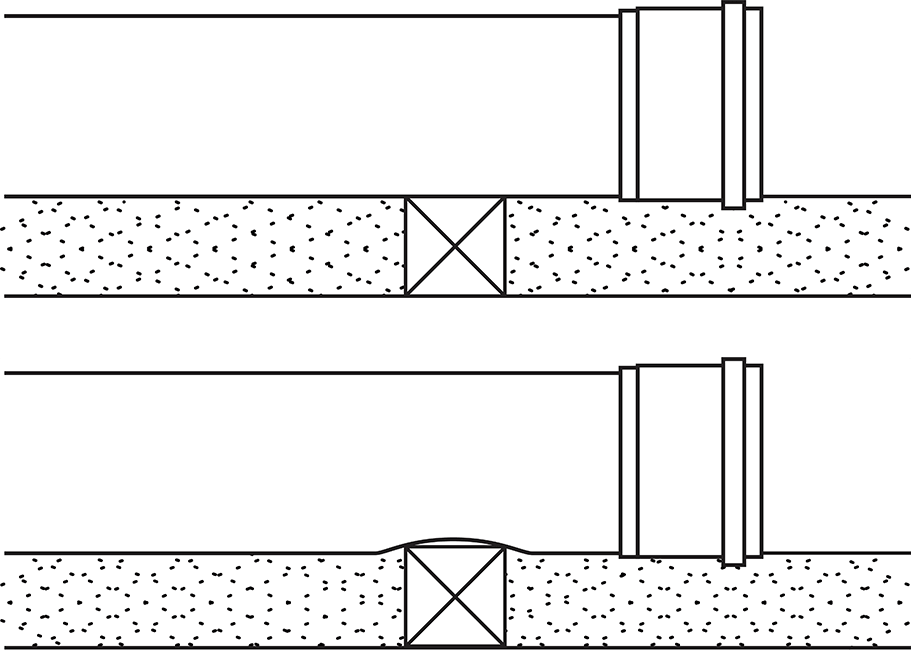

Inadequate encasement profile

It is not uncommon for a construction worker or construction supervisor, who is well-intended, to use concrete for the bedding in order to guarantee a perfect slope and to continue the encasement with gravelly materials in order to save on costs.

Plastic pipes (PVC, PE, PP) belong to the category of flexible pipes. Their encasement must be done according to SIA 190.

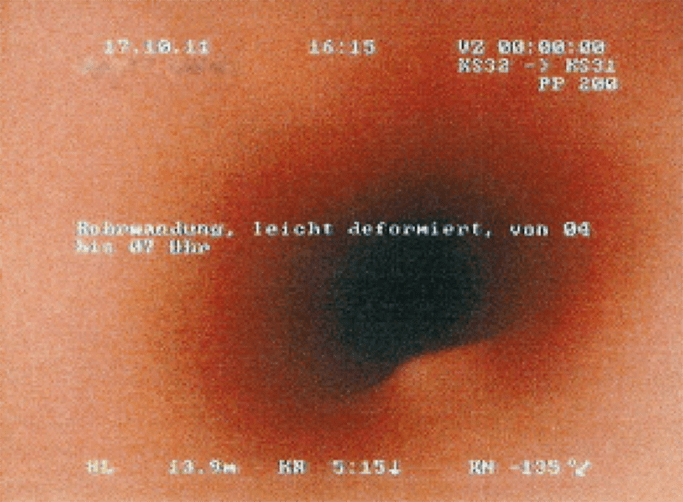

The realisation of a concrete bedding creates a hard point which concentrates the reaction of the ground under the base of the pipeline and deforms it.

A pebble on a concrete bedding will deform the base of the pipe during compaction. If the pipe is not very resistant to puncturing, the pipe may be perforated. In the case where the pipe is of higher quality, it will deform without perforation.